guyed tower VS free-standing tower

November 27, 2018

comparison of Self Supporting Tower to Guyed Mast Tower

December 2, 2018Steel Pole,Telescopic Pole,Steel Transmission Pole

The Steel Pole as specified in this Section shall conform to the latest edition of the following standards for operation in overhead lines in air under local ambient conditions. Design, Manufacture。Testing and Performance of the Steel Pole shall be in accordance with the followings or equivalent,International standards.

BS 729 : 1971 Hot dip galvanized coating on iron and steel articles or equivalent

BS 4190 : 1967 Isometric hexagonal Bolts, Screws and Nuts

BS 4360 Specification for weld able Structural Steel

BS 4870 Specification for approval testing of welding procedures.

BS 5649 : 1982 Part 4 Recommendations for surface protection of Metal Lighting

Columns

ASCE/48-05 Design of Steel Transmission Pole Structures

Dimensional Tolerances:

- i) The tolerance on thickness : – 0% to +10% on each sheet

- ii) Outside Diameter – 0% to +2%

iii) Length of Sections + 40mm

- iv) Telescopic Poles After assembly telescopic poles shall not exceed of

their stated length by + 75mm for 9m & 11m poles, gy +100 mm for 12m poles and +125 mm for 15m Pole.

- v) Straightness Straightness shall not exceed 1/300 of their height.

- vi) Thickness The minimum thickness of the material shall be 3

mm for a length of 3.0 meters section from the

bottom level

vii) Taper/Slope of Poles The side taper of the pole shall be between 15 mm

to 25 mm per meter length.

The design of pole shall be on the basis of minimum values considering tolerance.

Assembly of Telescopic Pole

Each pole shall be assembled in the factory and prior to assembly all seam welds on joint mating

surfaces shall be ground flush. All right spots in the galvanizing on mating surface shall be ground

and or fired flat. During the application of the compressive load to force the sections together, the joints shall be

agitated by striking them with timber or rubber mallets or by any other method as approved by the Engineer. The coating of galvanization shall not be damaged by this method of assembly.

STEEL POLES – ADVANTAGES & DISADVANTAGES

ADVANTAGES: Low cost, strength, multiple shapes, 15 to 30 year lifespan depending on environment, base plate & bolt circle flexibility, anchor base or direct burial.

DISADVANTAGES: Prone to corrosion & rust, heavy – larger equipment required to unload and install, higher maintenance requirements.

Related posts

In low-voltage transmission networks, which typically operate below 1,000 volts, galvanized steel poles provide a durable and environmentally friendly solution. This article explores the features, benefits, applications, and technical specifications of low voltage galvanized steel utility poles in transmission line projects.

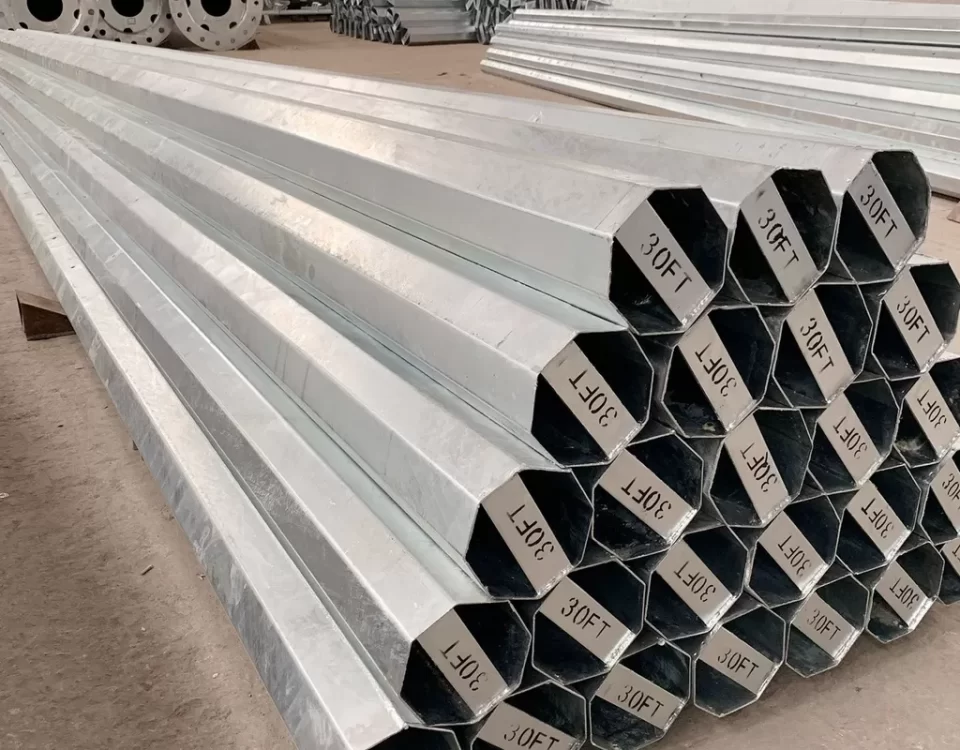

Hot Dip Galvanized Electrical Metal Utility Steel Pole for Railway in Shape Octagonal widely used in electrical power transmission railway station industry. In order to meet the increasingly higher demand for steel poles, our company design and produce many kinds of steel poles for the power transmission and distribution system. Besides, our electrical steel poles have been tested and approved by the Transmission Pole Tower Testing Station.