Galvanized Steel Electrical Utility Pole for Low Voltage Transmission Line

January 11, 2025

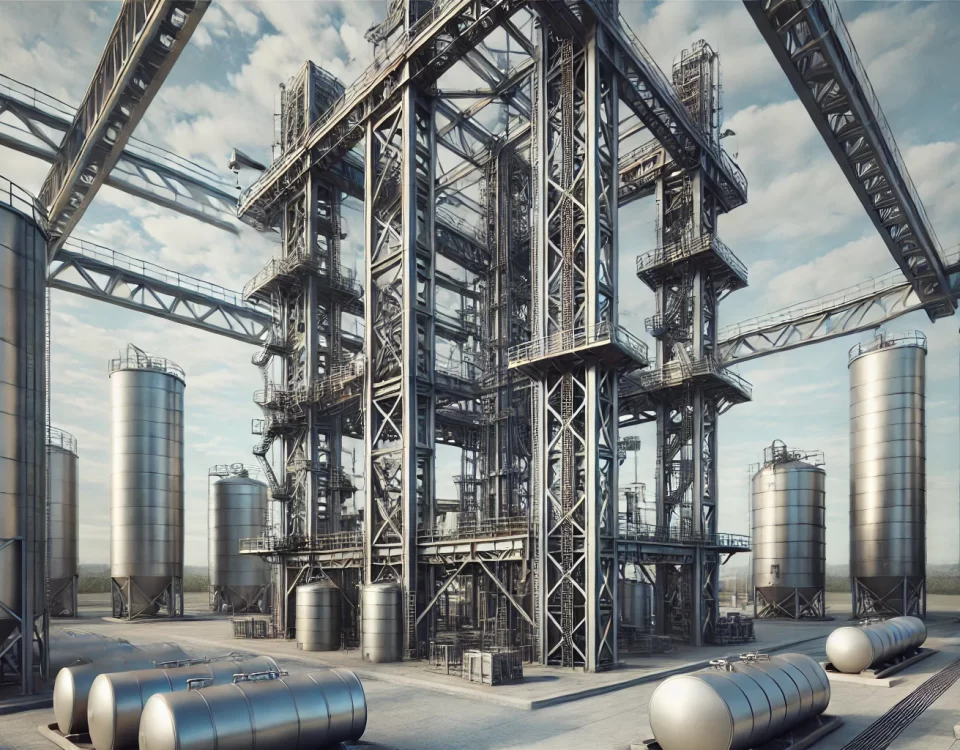

Tanks and Silos Support Tower

January 18, 2025Support Tower: Steel Support Towers and Their Fabrication

Support Tower: Steel Support Towers and Their Fabrication

Steel support towers play a critical role in industrial infrastructure, providing the stability and support needed for equipment, personnel, and various operational tasks. With their robust design, cost-effectiveness, and compliance with rigorous industry standards, steel support towers are the go-to choice for industries worldwide. Whether used in manufacturing plants, power stations, or petrochemical facilities, these structures ensure optimal performance while maintaining safety and durability.

Introduction to Steel Support Towers

Steel support towers are structural frameworks designed to support personnel or equipment in industrial settings. They are commonly found in factories, refineries, and other facilities where heavy equipment or elevated platforms are needed. These towers are designed with safety and durability in mind, making them a reliable solution for a variety of applications. By offering cost efficiency, ease of assembly, and long service life, steel support towers remain a vital component in modern industrial operations.

Key Features of Steel Support Towers

Steel support towers are engineered with specific features to meet the demands of industrial environments:

- Structural Integrity: Steel towers are capable of supporting heavy loads while maintaining stability under various conditions.

- Safety Features: Integrated stairs, handrails, and caged ladders ensure personnel safety during operations.

- Compact Design: Pre-fabricated components make these towers versatile and easy to install in diverse environments.

- High Durability: Made from high-grade steel, these towers resist wear and tear, ensuring long-term functionality.

Applications of Steel Support Towers

Steel support towers are used across a variety of industries, each with unique demands:

- Industrial Manufacturing Facilities:

Provide platforms for machinery, maintenance personnel, and storage. - Chemical and Petrochemical Plants:

Support equipment used in refining and chemical processing, ensuring safe and stable operations. - Power Generation Sites:

Offer structural support for turbines, transformers, and other electrical equipment. - Construction and Maintenance Projects:

Serve as scaffolding or support frameworks during large-scale construction projects.

Advantages of Steel Support Towers

- Cost-Effectiveness: Steel towers are more affordable compared to other structural supports due to lower material costs and efficient manufacturing.

- Durability: Their corrosion-resistant coatings and robust design allow them to perform in harsh conditions for decades.

- Versatility: Steel towers can be customized to meet the unique needs of any industry.

- Minimal Maintenance: Once installed, they require little upkeep, reducing long-term operational costs.

Design and Engineering of Steel Support Towers

The design of steel support towers is a critical process that ensures structural safety and efficiency. Modern engineering tools, such as Finite Element Analysis (FEA), are used to simulate real-world stresses and optimize tower design. Compliance with industry standards ensures that the towers can withstand various loads, including environmental factors like wind and earthquakes.

Support Tower Fabrication Process

At leading fabrication facilities, the process of creating steel support towers involves:

- Design and Simulation: Engineers use advanced software to model and simulate the tower’s structure, ensuring optimal strength and efficiency.

- In-House Fabrication: All components are fabricated within a single facility to ensure quality and precision.

- Shipping Optimization: Instead of shipping pre-assembled towers, individual parts are transported, reducing costs.

Transportation and Assembly

The modular nature of steel support towers allows for efficient transport and assembly:

- Transport: Parts are shipped as individual components to minimize space and costs.

- On-Site Assembly: Highly trained personnel assemble the towers using bolted or welded configurations, ensuring fast and error-free construction.

Safety Measures in Steel Support Towers

To protect workers and ensure safe operations, steel support towers are equipped with:

- Caged Ladders: Prevent falls during climbing.

- Handrails: Offer stability and safety on elevated platforms.

- Regulated Design: Adherence to safety standards minimizes risks during operation and assembly.

Compliance and Standards in Steel Tower Fabrication

The fabrication of steel support towers is governed by strict regulations covering:

- Steel Grades and Types: Only certified materials are used.

- Structural Welding Standards: Ensures strong and durable connections.

- Inspection Protocols: Regular inspections guarantee safety and functionality.

Comparison with Alternative Support Methods

Compared to other structural support methods, steel towers stand out in terms of:

- Cost: Steel towers are more economical than concrete or wooden structures.

- Durability: Steel’s strength and corrosion resistance ensure a longer lifespan.

- Flexibility: Customizable designs make steel towers suitable for diverse applications.

Maintenance and Longevity of Steel Support Towers

Steel support towers require minimal maintenance to remain in optimal condition. Routine inspections, combined with anti-corrosion treatments, can extend their lifespan by decades. Pre-applied protective coatings ensure that even harsh environments do not compromise their integrity.

Cost Efficiency of Steel Support Towers

The pre-fabricated nature of these towers minimizes on-site work, reducing labor costs. Additionally, modular parts reduce shipping expenses, making steel towers a cost-effective choice for industrial projects.

Challenges in Steel Support Tower Fabrication

Some challenges include:

- High Material Costs: High-grade steel can be expensive.

- Installation in Remote Areas: Transporting and assembling towers in remote locations can be logistically challenging.

Innovations in Steel Tower Fabrication

The future of steel support towers lies in:

- Modular Designs: Allowing towers to be reconfigured for different applications.

- Advanced Welding Techniques: Ensuring stronger and faster assembly.

- Lightweight Alloys: Improving strength while reducing overall weight.

Support Tower: Steel Support Towers and Their Fabrication

Steel support towers are critical components in industrial infrastructure. Their robust designs, cost efficiency, and compliance with industry standards make them indispensable in applications ranging from power generation to petrochemical facilities. To enhance understanding, this article includes technical parameter tables and real-world customer case studies to showcase their practicality and effectiveness.

Technical Parameters of Steel Support Towers

The following table outlines the key parameters used to design and fabricate steel support towers:

| Parameter | Description |

|---|---|

| Material | High-grade structural steel (e.g., ASTM A36, A572, A588) |

| Load-Bearing Capacity | Up to 50 tons, depending on tower height and configuration |

| Height Range | 5–80 meters (customizable to project needs) |

| Weight | Varies with size; typically 10–50% lighter than concrete alternatives |

| Coating Options | Hot-dip galvanization, epoxy paint, powder coating for corrosion resistance |

| Wind Resistance | Designed to withstand wind speeds of up to 250 km/h (depending on location) |

| Seismic Resistance | Engineered to withstand Zone 4 seismic events |

| Safety Features | Ladders with cages, handrails, anti-slip stairs |

| Assembly Time | 30–50% faster than traditional structures |

| Standards Compliance | ISO 9001, ANSI/AISC 360, AWS D1.1 (welding), and Eurocode 3 |

Steel Support Tower Design Configurations

Steel support towers can be tailored for specific purposes, with variations in height, load capacity, and safety features. Below is an example of design variations by application:

| Application | Height (m) | Load Capacity (tons) | Safety Features | Coating |

|---|---|---|---|---|

| Telecommunications Tower | 10–50 | 5–20 | Ladder cage, handrails | Hot-dip galvanized |

| Petrochemical Platforms | 5–30 | 10–40 | Anti-slip stairs, fire-resistant paint | Epoxy + fire coating |

| Power Substation Support | 20–60 | 15–50 | Ladders, fall arrest systems | Galvanized + UV protection |

| Maintenance Platforms | 5–15 | 2–10 | Railings, slip-resistant flooring | Powder-coated steel |

Customer Case Studies: Real-World Applications

Case Study 1: Telecommunications Tower in Urban Environment

- Customer: A leading telecom operator in Southeast Asia

- Project Overview: The company required 50 steel towers, each 40 meters tall, for 5G antennas in an urban setting.

- Challenges: Limited space for construction, high wind speeds in coastal areas, and the need for corrosion resistance due to humidity.

- Solution:

- Towers were fabricated using ASTM A588 steel with a hot-dip galvanized coating for corrosion resistance.

- Compact modular design enabled faster assembly on-site without the need for heavy equipment.

- Towers were wind-resistant up to 220 km/h.

- Outcome: The project was completed in 4 months, reducing downtime and ensuring the seamless rollout of 5G networks.

Case Study 2: Steel Support Towers for Petrochemical Facility

- Customer: A multinational petrochemical company operating in the Middle East

- Project Overview: Installation of steel support towers to hold refinery equipment and provide safe access for maintenance.

- Challenges: High temperatures, chemical exposure, and seismic activity in the region.

- Solution:

- Towers were fabricated with fire-resistant epoxy coatings and engineered for seismic resistance.

- Ladder cages and handrails were integrated to ensure worker safety.

- Modular sections minimized the on-site welding required.

- Outcome: The support towers operated flawlessly, reducing maintenance-related downtimes by 30%.

Case Study 3: Renewable Energy Tower for Wind Turbines

- Customer: A renewable energy provider in Northern Europe

- Project Overview: Steel towers were needed to support small wind turbines in a coastal environment.

- Challenges: Corrosion risk from saltwater exposure and the need for lightweight, flexible structures.

- Solution:

- Towers were built using lightweight steel alloys and hot-dip galvanization.

- Designed to withstand wind speeds exceeding 250 km/h.

- Pre-fabricated parts ensured easy transport to remote areas.

- Outcome: The towers increased wind turbine efficiency by 15% due to their aerodynamic design and stability.

Economic Benefits of Steel Support Towers

Steel support towers provide substantial cost advantages over traditional materials such as concrete or wood. Here’s an analysis of cost efficiency:

| Cost Aspect | Steel Towers | Concrete/Other Towers |

|---|---|---|

| Initial Material Cost | Slightly higher than wood | Lower for raw materials |

| Transportation | Modular parts reduce shipping costs | Heavy structures increase costs |

| Assembly Time | 30–50% faster due to pre-fabrication | Time-intensive, requiring more manpower |

| Maintenance Costs | Low (corrosion-resistant coatings) | High (frequent repairs needed) |

| Lifespan | 50+ years with minimal maintenance | Shorter lifespan, especially in harsh environments |

Steel Support Tower Market Overview

The market for steel support towers is growing rapidly, driven by demand in sectors such as telecommunications, renewable energy, and petrochemicals. Below is a snapshot of the market dynamics:

| Market Segment | Growth Drivers | Examples |

|---|---|---|

| Telecommunications | 5G rollout, need for higher bandwidth, urban infrastructure development | Cellular towers, broadcast towers |

| Renewable Energy | Expansion of wind and solar power projects | Wind turbine supports, solar panel mounts |

| Oil and Gas | Exploration of offshore and onshore reserves | Offshore platforms, pipeline supports |

| Industrial Applications | Increased manufacturing and process plant expansions | Maintenance platforms, equipment supports |

Key Takeaways for Customers

Steel support towers are among the most reliable and versatile solutions for structural support in industrial environments. For businesses considering their use, here are some critical factors to keep in mind:

- Customization: Work with a supplier that offers tailored designs to meet your specific application requirements.

- Material Quality: Opt for towers made from high-grade steel with appropriate coatings for your environmental conditions.

- Compliance: Ensure that the tower complies with relevant international and local standards for safety and durability.

- Long-Term Costs: Consider the cost benefits of minimal maintenance, durability, and extended service life compared to alternative materials.

Conclusion

Steel support towers provide unparalleled benefits in terms of durability, safety, and cost-efficiency. Their versatility allows them to meet the demands of a wide range of industrial applications, from telecommunications to renewable energy and beyond. Advances in fabrication techniques, coupled with sustainable and innovative designs, are ensuring that steel towers remain the preferred choice for infrastructure projects worldwide.

For industries looking to invest in reliable structural solutions, steel support towers offer a combination of strength, flexibility, and long-term economic value.