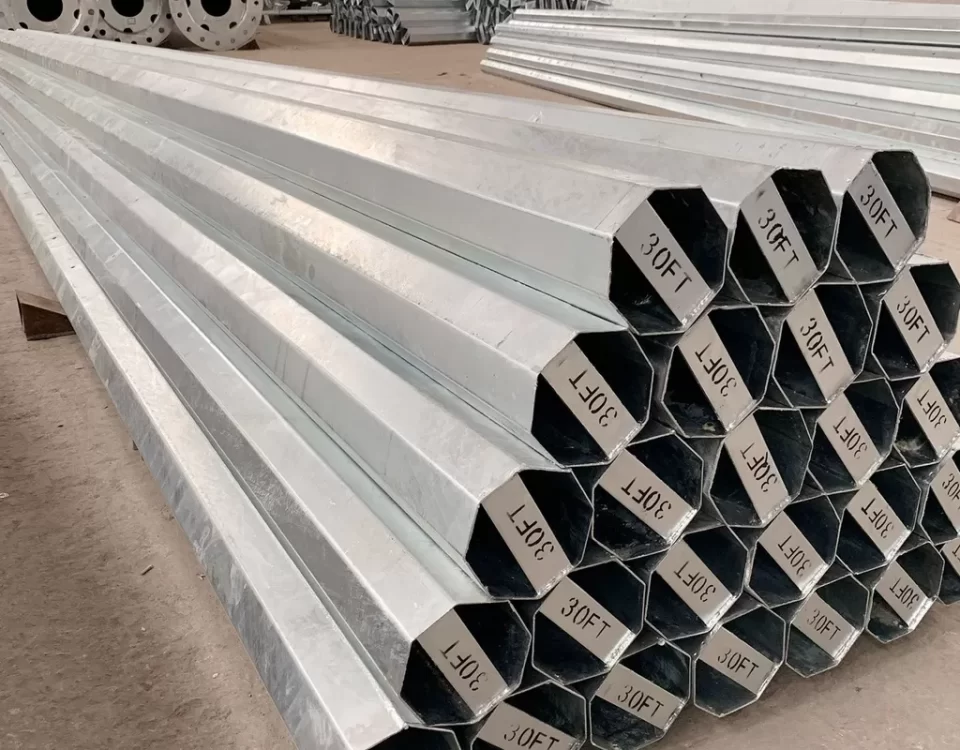

Galvanized Steel Electrical Power Pole for Transmission Line – HDG Polygonal Shape

April 11, 2018

400KV Transmission Line Lattice Steel Tower Design drawings Requirements

April 15, 2018Transmission Line Galvanized Steel Tubular Pole 10KV to 500KV

Keeping in mind the diverse requirements of the clients, we offer a wide range of Tubular Steel Pole that is used for installation of lights on streets and highways.

By utilizing advanced tools and quality assured steel, our adroit professionals manufacture this pole in sync with the set industry standards.

Owing to its resistance to corrosion and robust design, the offered pole has gained high appreciation among our patrons. Moreover, we offer this pole in various standard sizes and designs at budget friendly prices.

Features: Tubular Steel Polee

Ability to withstand harsh weathering conditions

High endurance

Anti-corrosive

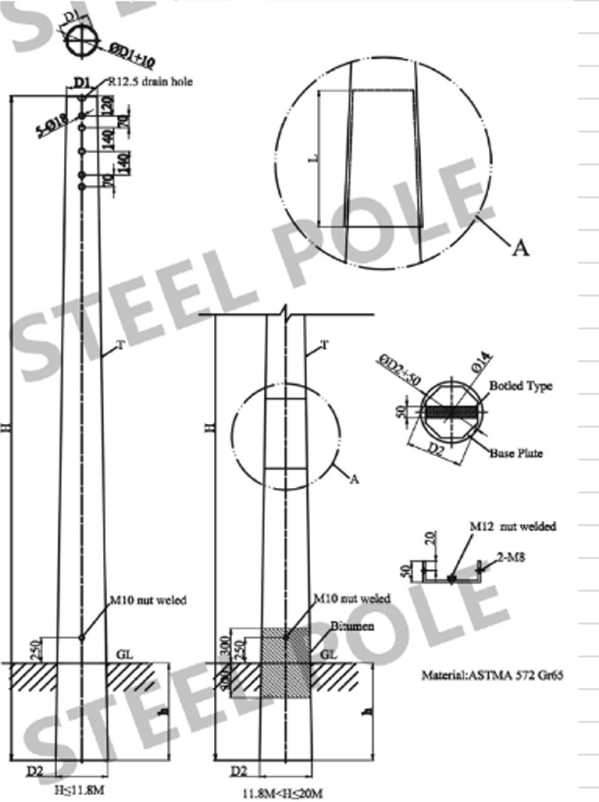

Character Sheet as shown in the diagram

D1 Top diameter of steel pole

D2 Bottom diameter of steel pole

H Total Height

h Burial Length

T Thickness

|

African electric |

Doles date sheet |

||||||||||||

|

H(mm; |

F(KN) |

5 |

6.5 |

8 |

10 |

12.5 |

16 |

20 |

25 |

32 |

40 |

50 |

|

|

10 |

D1 (mm) |

180 |

190 |

200 |

210 |

220 |

225 |

240 |

240 |

265 |

320 |

325 |

|

|

D2 (mm) |

360 |

400 |

415 |

455 |

500 |

545 |

565 |

590 |

625 |

675 |

770 |

||

|

T (mm) |

3 |

3 |

3.5 |

3.5 |

3.75 |

4 |

4.5 |

5 |

6 |

6 |

6 |

||

|

h(m) |

1.6 |

1.6 |

1.6 |

1.6 |

1.6 |

1.6 |

1.6 |

1.6 |

1.6 |

1.6 |

1.6 |

||

|

11 |

D1 (mm) |

180 |

190 |

200 |

200 |

220 |

225 |

240 |

250 |

265 |

320 |

325 |

|

|

D2 (mm) |

380 |

400 |

440 |

465 |

530 |

575 |

590 |

640 |

650 |

730 |

810 |

||

|

T (mm) |

3 |

3.5 |

3.5 |

3.75 |

3.75 |

4 |

4.5 |

5 |

6 |

6 |

6 |

||

|

h(m) |

1.8 |

1.8 |

1.8 |

1.8 |

1.8 |

1.8 |

1.8 |

1.8 |

1.8 |

1.8 |

1.8 |

||

|

11.8 |

D1 (mm) |

180 |

190 |

200 |

210 |

220 |

225 |

240 |

250 |

265 |

320 |

325 |

|

|

D2 (mm) |

400 |

410 |

455 |

490 |

550 |

595 |

630 |

665 |

680 |

755 |

845 |

||

|

T (mm) |

3 |

3.5 |

3.5 |

3.75 |

3.75 |

4 |

4.5 |

5 |

6 |

6 |

6 |

||

|

h(m) |

1.9 |

1.9 |

1.9 |

1.9 |

1.9 |

1.9 |

1.9 |

1.9 |

1.9 |

1.9 |

1.9 |

||

|

13 |

D1 (mm) |

180 |

190 |

200 |

210 |

220 |

225 |

240 |

250 |

265 |

320 |

325 |

|

|

D2 (mm) |

400 |

430 |

465 |

530 |

585 |

640 |

670 |

705 |

710 |

800 |

895 |

||

|

T (mm) |

3.5 |

3.75 |

3.75 |

3.75 |

3.75 |

4 |

4.5 |

5 |

6 |

6 |

6 |

||

|

h(m) |

2.1 |

2.1 |

2.1 |

2.1 |

2.1 |

2.1 |

2.1 |

2.1 |

2.1 |

2.1 |

2.1 |

||

|

14 |

D1 (mm) |

180 |

190 |

200 |

210 |

220 |

225 |

240 |

250 |

260 |

320 |

325 |

|

|

D2 (mm) |

410 |

450 |

490 |

550 |

605 |

670 |

700 |

735 |

735 |

835 |

935 |

||

|

T (mm) |

3.5 |

3.75 |

3.75 |

3.75 |

3.75 |

4 |

4.5 |

5 |

6 |

6 |

6 |

||

|

h(m) |

2.3 |

2.3 |

2.3 |

2.3 |

2.3 |

2.3 |

2.3 |

2.3 |

2.3 |

2.3 |

2.3 |

||

|

16 |

D1 (mm) |

180 |

190 |

200 |

210 |

220 |

225 |

240 |

250 |

265 |

320 |

325 |

|

|

D2 (mm) |

445 |

470 |

530 |

585 |

650 |

725 |

750 |

800 |

815 |

900 |

930 |

||

|

T (mm) |

3.75 |

4 |

4 |

4 |

4 |

4 |

4.5 |

5 |

6 |

6 |

7 |

||

|

h(m) |

2.6 |

2.6 |

2.6 |

2.6 |

2.6 |

2.6 |

2.6 |

2.6 |

2.6 |

2.6 |

2.6 |

||

|

18 |

D1 (mm) |

180 |

190 |

200 |

210 |

220 |

225 |

240 |

250 |

265 |

320 |

325 |

|

|

D2 (mm) |

475 |

510 |

570 |

620 |

700 |

765 |

820 |

860 |

875 |

965 |

965 |

||

|

T (mm) |

3.75 |

4 |

4 |

4 |

4 |

4 |

4.5 |

5 |

6 |

6 |

8 |

||

|

h(m) |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

||

|

20 |

D1 (mm) |

180 |

190 |

200 |

210 |

220 |

225 |

240 |

250 |

265 |

320 |

325 |

|

|

D2 (mm) |

490 |

560 |

615 |

680 |

770 |

840 |

870 |

915 |

920 |

950 |

990 |

||

|

T (mm) |

4 |

4 |

4 |

4 |

4 |

4 |

4.5 |

5 |

6 |

7 |

8 |

||

|

h(m) |

3.3 |

3.3 |

3.3 |

3.3 |

3.3 |

3.3 |

3.3 |

3.3 |

3.3 |

3.3 |

3.3 |

||

|

Type

|

Transmission Line Galvanized Steel Tubular Pole 10KV to 500KV |

|

Suit for

|

Electricity distribution

|

|

Shape

|

Conoid ,Multi-pyramidal,Columniform,polygonal or conical

|

|

Material

|

Hot Roll Steel Q235, Q345, Q420, Q460, ASTM A527 A36, GR50, GR65, ST-37, ST-44, ST-52, S355JR, S355J2G3, SS41, SS50, SS55 and others equivalent steel material |

|

Design Load in Kg

|

300~ 1000 Kg appliced to 50cm from the to pole

|

|

Marks

|

Name palte through rivert or glue ,engrave ,emboss as per customer requirement

|

|

Surface treatment

|

Hot dip galvanized Following ASTM A 123, color polyester power or any other standard by client required

|

|

Joint of Poles

|

Insert mode,innerflange mode,face to face joint mode

|

|

Design of pole

|

Against earthquake of 8 grade

|

|

Wind Speed

|

160 Km/Hour . 30 m /s

|

|

Length of per section

|

Within 14m once forming without slip joint

|

|

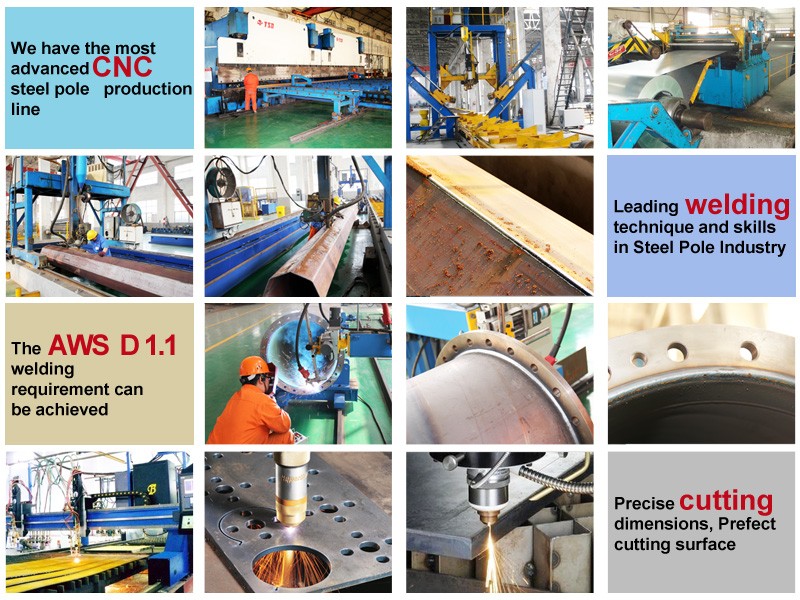

Welding

|

Welding complies with AWS D1.1 standard. CO2 welding or submerged arc auto methods No fissure, scar, overlap, layer or other defects Internal and external welding makes the pole more beautiful in shape If customers need any other requirements of welding, we also can make adjustment ad your request |

|

Thickness

|

1 mm to 30 mm

|

|

Production Process

|

Rew material test → Cuttingj →Molding or bending →Welidng (longitudinal )→Dimension verify →Flange welding→Hole drilling →Calibration → Deburr→Galvanization or powder coating ,painting →Recalibration →Thread →Packages

|

|

Packages

|

Our poles as normal cover by Mat or straw bale at the top and bottom ,anyway also can following by client required , each 40HC or OT can loading how many pcs will calculation base on the client actually specification and data

|

Steel Tubular Pole 10KV to 500KV Production process

As an BV ,ISO ,SGS approved supplier in China ,we have more than 20 years produce and export steel pole ,and we can assure the pole we offered is of sound quality which made from qualified material with our professional workers and advance equipment .

Material

All of our material are purchased from famous mill factory to assure the quality

A mill certificate issued by the mill factory with stamp and signature must be provided before unload the material in our factory ,otherwise we have our reason to refuse the material .

Before put into production ,all the material must pass the chemical and physical analysis to make sure that they have meet the requested strength and component.

Related posts

In low-voltage transmission networks, which typically operate below 1,000 volts, galvanized steel poles provide a durable and environmentally friendly solution. This article explores the features, benefits, applications, and technical specifications of low voltage galvanized steel utility poles in transmission line projects.

Hot Dip Galvanized Electrical Metal Utility Steel Pole for Railway in Shape Octagonal widely used in electrical power transmission railway station industry. In order to meet the increasingly higher demand for steel poles, our company design and produce many kinds of steel poles for the power transmission and distribution system. Besides, our electrical steel poles have been tested and approved by the Transmission Pole Tower Testing Station.