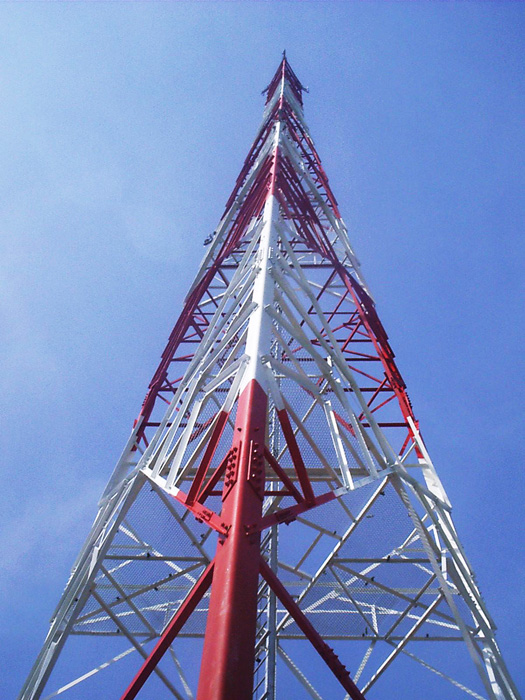

four leg self-supporting towers(SST)

October 6, 2018

Steel Lattice Towers for Power Transmission up to 500 KV

October 29, 2018Galvanized Lattice Angle Steel Power Transmission Line Tower

Galvanized Lattice Angle Steel Power Transmission Line Tower

| Name | 500KV Hot dipped galvanized transmission line |

| Material | Q235 or Q345 |

| Voltage Grade | 10KV, 110KV, 220KV, 500KV or others |

| Height | 10-105m |

| Wind Pressure | 210Km/h |

| Surface Coating | Hot Dip Galvanization or Painting |

| Welding | CO2 welding or Submerged arc auto methods |

| Spare Parts | Parts for connection or installation will be provided |

| Lifetime | More than 25 years |

| Capacity | 5000 tons/month |

| Project Experience | Main oversea area:South-east Asia,Europe,South America,Oceania,etc |

spare parts of the Galvanized Lattice Angle Steel Power Transmission Line Tower

CLAMPS AND BOLTS

Clamps, which are fastened with bolts, shall be provided with breakaway heads or caps and suitable washers. The bolts shall be lubricated with an appropriate lubricant.

The clamps shall be designed so that they will seat firmly and smoothly on the conductor with sufficient pressure to compensate for creep, cold flow, and/or nesting.

The arm clamp shall be of aluminum alloy commensurate with the design requirements. The clamp cap shall also be of aluminum alloy.

The arm clamp and clamp cap shall each have an effective length in bearing on the conductor of not less than 70 mm for metal surfaced clamps. Exit radii shall be excluded in meeting this requirement.

Bolted type spacer assembly clamps shall be capable of withstanding a torque equal to twice of nominal design installation torque, without failure of component parts when installed on the conductor. This value shall be obtained by applying the torque to the lower head of the breakaway bolt or cap screw.

Clamping bolts shall be M16 aluminum alloy or minimum M12 stainless steel with a break-away type shear head bolt the break-away shear head type bolt or break-away cap screw for galvanized steel bolts shall be furnished with a wrench stop to prevent the socket from engaging the lower head during installation.

The torque required to break away the upper head from the lower head shall be within a tolerance of plus or minus ten percent of the Supplier’s design value.

The break-away head bolts or cap screws shall be fabricated from 6101-T8 or AA7075 high strength aluminum alloy or stainless steel (austenitic stainless steel ANSI 300 series) or low or medium carbon steel and in accordance to ISO 898 property class either 8.8 or 6.8 together with hexagonal nuts of appropriate class. Any other material must be approved by the Engineer.

The anodization for aluminum alloy shall be according to US Military Specifications MIL A-8025C.

Clamping bolts or cap screws are to be equipped with steel belleville type spring washers designed to compensate for a potential relaxation in bolt tension, the washer(s) shall be displaced at least 50% of the total as-flat deflection at nominal installation torque, the washer(s) shall have a recoverable deflection of at least 0.9 mm as determined by the difference between the loaded and subsequent unloaded height. The Supplier can use two Belleville washers to control the clamp bolt loosening.

The material of belleville washer and other spring elements are made of 50CrV4 chromium-vanadium steel or Ck75 unalloyed steel.

Bolt Torque Test

The four clamps of the spacer damper assembly shall be attached to the AAAC “Greeley” conductor or to a bar of 28.14 ±0.254 mm diameter. Torque shall be applied to the upper head of each break-away bolt. The head shall not break away at a value other than the Supplier’s design installation torque plus or minus ten percent. The torque required to break away each upper head shall be recorded.

At a torque of twice of nominal design installation torque there shall be no failure of component parts. The torque shall then be recorded.

Records shall be made of the lower head withstand torque, failure torque, and the part(s) of the clamp assemblies that fail.