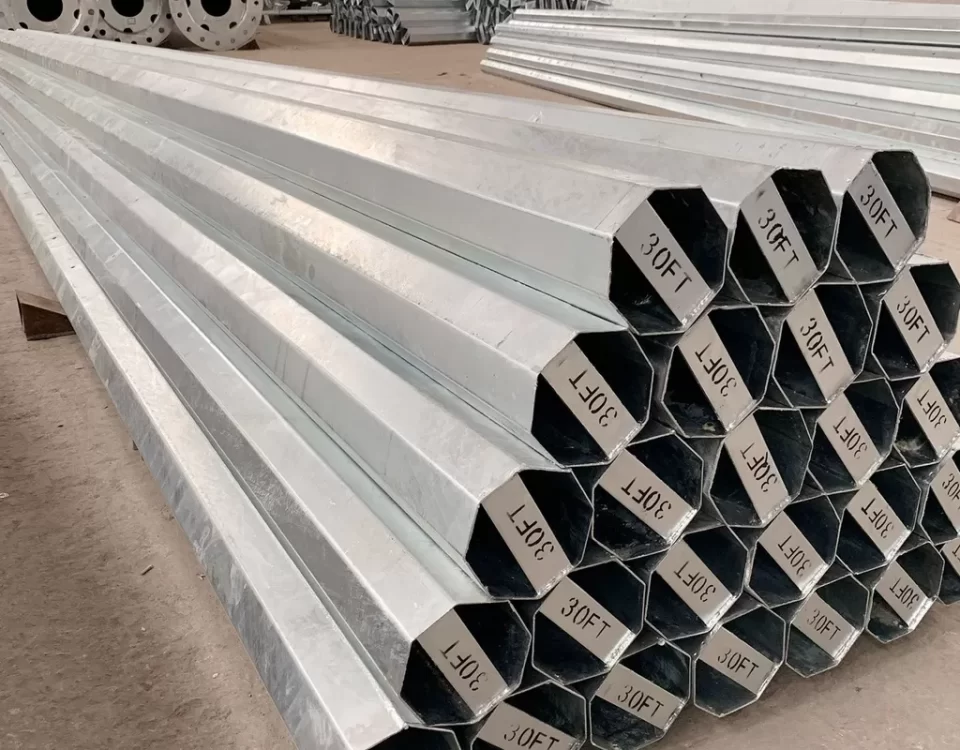

Polygonal Tubular Galvanized Steel Structural Electric Power Steel Pole

January 8, 2025

Support Tower: Steel Support Towers and Their Fabrication

January 15, 2025Galvanized Steel Electrical Utility Pole for Low Voltage Transmission Line

In low-voltage transmission networks, which typically operate below 1,000 volts, galvanized steel poles provide a durable and environmentally friendly solution. This article explores the features, benefits, applications, and technical specifications of low voltage galvanized steel utility poles in transmission line projects.

Low Voltage Galvanized Electrical Steel Utility Pole for Transmission Line

Introduction to Low Voltage Galvanized Electrical Steel Utility Poles

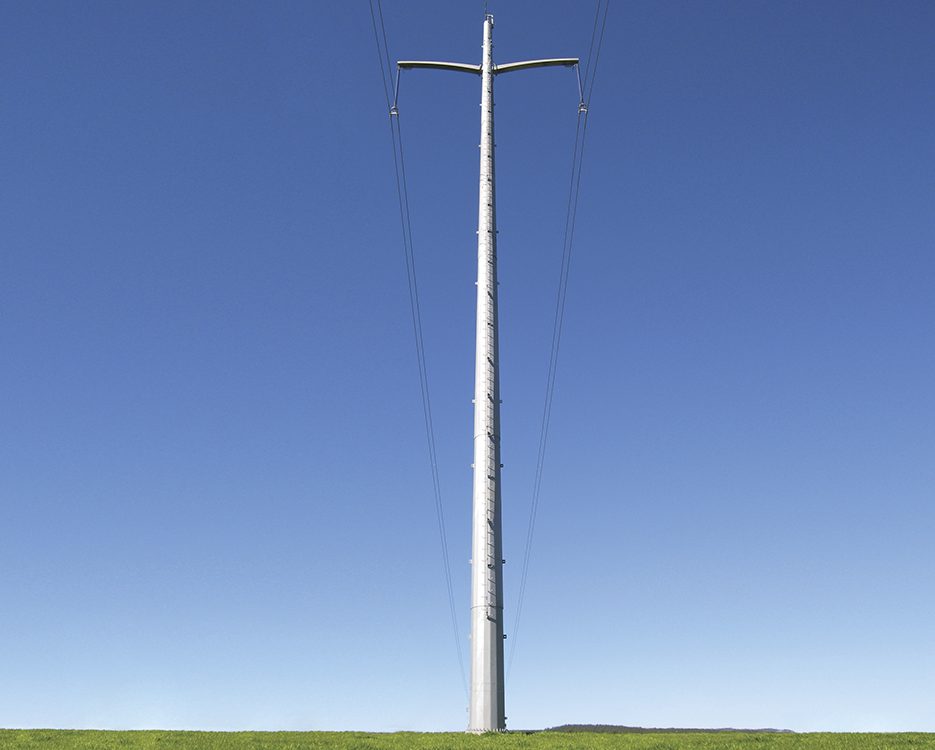

Low voltage galvanized electrical steel utility poles are a vital component of modern energy distribution systems. These poles are engineered to support low-voltage transmission lines that carry electricity from substations to end users. Their design ensures reliability, longevity, and cost-efficiency, making them a preferred alternative to traditional wooden and concrete poles.

In low-voltage transmission networks, which typically operate below 1,000 volts, galvanized steel poles provide a durable and environmentally friendly solution. This article explores the features, benefits, applications, and technical specifications of low voltage galvanized steel utility poles in transmission line projects.

Product Specifications

| Attribute | Details |

|---|---|

| Product Name | Low Voltage Hot Dip Galvanized Electrical Steel Utility Pole for Transmission Line |

| Type | Burial Type |

| Voltage Grade | 10~500KV (10KV, 13.8KV, 33KV, 35KV, 66KV, 110KV, 132KV, 220KV, 230KV, 330KV, 500KV or Others) |

| Height | ≥ 7 M |

| Shape | Conical / Round / Polygonal (Octagonal, Dodecagonal, Hexadecagonal, etc.) |

| Material | Hot Roll Steel Sheet Q345, GR50 (Equivalent to S355JR) |

| Min Yield Stress | 345 Mpa |

| Tensile Strength | 470 Mpa ~ 630 Mpa |

| Wall Thickness | 3 ~ 20 mm |

| Once Forming | Up to 14 m without joint (for container lengths ≤ 12 m, poles may be made in multiple segments) |

| Welding | Complies with AWS D1.1 standard, using CO2 welding or submerged arc automatic methods. |

| Joint Type | Insert Mode, Flange Mode |

| Base Plate | Square/Round/Polygonal base plate with slotted holes for anchor bolts installation. |

Introduction to Low Voltage Hot Dip Galvanized Electrical Steel Utility Poles

Low Voltage Hot Dip Galvanized Electrical Steel Utility Poles are designed to support transmission lines ranging from 10KV to 500KV, ensuring efficient and reliable energy distribution for a variety of applications. These poles are manufactured using Q345/GR50 hot-rolled steel sheets, which provide exceptional strength, durability, and resistance to harsh environmental conditions.

Hot-dip galvanization, the primary protective coating applied to the poles, extends their lifespan by safeguarding against corrosion, ensuring reliable performance in both urban and rural environments. These poles are available in a variety of shapes, including conical, round, octagonal, dodecagonal, and other polygonal configurations, making them versatile for diverse infrastructure requirements.

Key Features and Specifications

1. Voltage Grade

The poles are suitable for low to medium voltage transmission and distribution networks, with a voltage range of 10KV to 500KV, covering multiple configurations:

- Common Voltage Grades: 10KV, 33KV, 66KV, 110KV, 132KV, 220KV, 330KV, and 500KV.

This range ensures adaptability to different transmission line requirements.

2. Height

- Standard height starts at ≥7 meters, with customized designs to suit project specifications.

- For larger projects requiring poles over 14 meters, segment joints are used to meet logistical and transportation constraints.

3. Shape

- Poles are available in conical, round, and polygonal shapes.

- Polygonal Options: Octagonal, dodecagonal, hexadecagonal, and other configurations tailored to project needs.

4. Material

- Made from Q345 (GR50) hot-rolled steel sheets, equivalent to S355JR, which ensures:

- Minimum Yield Stress: 345 MPa.

- Tensile Strength: 470 MPa ~ 630 MPa.

5. Wall Thickness

- Wall thickness ranges from 3 mm to 20 mm, providing flexibility in load-bearing capacities and structural durability.

6. Welding and Fabrication

- Welding Standards: All welding complies with AWS D1.1 standards, ensuring structural integrity.

- Features CO2 welding or submerged arc automatic welding methods, guaranteeing:

- No fissures, scars, overlaps, or other defects.

- 100% complete penetration welds for internal and external surfaces.

7. Base Plate and Joint Options

- Base Plates: Available in square, round, or polygonal shapes with slotted holes for anchor bolt installation.

- Joint Types: Insert mode and flange mode for seamless assembly of multi-segment poles.

8. Length and Transportation

- Once Forming: Up to 14 meters without a joint, ensuring robust structural integrity.

- For poles longer than 12 meters, multi-segment designs accommodate 40GP/40HQ container logistics.

Manufacturing Process of Hot Dip Galvanized Electrical Steel Poles

| Step | Description |

|---|---|

| 1. Material Selection | Use of Q345/GR50 steel sheets with high yield strength and tensile capacity. |

| 2. Cutting and Shaping | Steel sheets are cut and shaped into round, conical, or polygonal profiles. |

| 3. Welding | Welded using submerged arc or CO2 methods for internal and external seams. |

| 4. Galvanization | Hot-dip galvanization ensures complete corrosion protection with a uniform coating. |

| 5. Quality Control | Compliance with ISO 9001, AWS D1.1, and other standards to ensure durability. |

Applications of Low Voltage Galvanized Utility Poles

1. Low Voltage Power Transmission and Distribution

These poles are widely used for low voltage networks in:

- Rural areas, ensuring reliable power supply to underserved communities.

- Urban areas, for safe and efficient distribution to residential and commercial establishments.

2. Telecommunications Support Poles

- Used to support telecommunication lines or antennas for cellular networks.

3. Renewable Energy Integration

- Perfect for solar and wind energy projects to transmit renewable energy from generation sites to end users.

4. Street Lighting Infrastructure

- Ideal for supporting streetlights and traffic management systems.

5. Substation Connections

- Low voltage poles connect substations to distribution lines, forming the backbone of localized power grids.

Advantages of Low Voltage Galvanized Electrical Steel Utility Poles

| Feature | Benefit |

|---|---|

| Hot-Dip Galvanization | Provides corrosion resistance, ensuring a lifespan of 50+ years. |

| High Strength-to-Weight Ratio | Ensures structural stability while remaining lightweight for easier transportation. |

| Customizable Design | Shapes, heights, and wall thickness can be tailored to meet project specifications. |

| Recyclability | 100% recyclable, reducing environmental impact. |

| Low Maintenance | Minimal upkeep required due to the durable zinc coating. |

| Cost-Effective | Long-term durability reduces total lifecycle costs. |

Comparison with Alternative Materials

| Attribute | Galvanized Steel Poles | Wooden Poles | Concrete Poles |

|---|---|---|---|

| Durability | 50+ years | 10–20 years | 30–40 years |

| Corrosion Resistance | High (Zinc coating protection) | Low | Moderate |

| Load Capacity | High | Low | Moderate |

| Maintenance | Minimal | High (treatment needed) | Moderate |

| Environmental Impact | Recyclable, eco-friendly | Deforestation required | Energy-intensive manufacturing |

| Cost | High initial, low lifecycle costs | Low initial, high lifecycle costs | Moderate |

Technical Specifications Summary

| Attribute | Specification |

|---|---|

| Voltage Grade | 10KV–500KV |

| Material | Q345 (GR50) hot-rolled steel |

| Height | ≥7 m |

| Wall Thickness | 3–20 mm |

| Tensile Strength | 470 MPa ~ 630 MPa |

| Welding Standard | AWS D1.1 |

| Galvanization Coating | 85–100 microns |

| Shapes | Conical, round, polygonal (octagonal, etc.) |

Key Features of Low Voltage Galvanized Electrical Steel Utility Poles

Durability and Longevity

Galvanized steel utility poles are designed to last for decades. The galvanization process, which involves coating the steel with zinc, ensures that the poles are protected from rust and corrosion. This makes them ideal for long-term applications in harsh environments.

Corrosion Resistance in Low Voltage Applications

Corrosion is one of the biggest challenges for transmission poles, especially in coastal or high-humidity areas. The zinc coating on galvanized steel poles forms a protective barrier, preventing moisture and oxygen from reaching the steel core.

Strength-to-Weight Ratio and Load Capacity

Galvanized steel poles are lightweight yet strong, offering superior load-bearing capacity compared to wood or concrete. This makes them suitable for supporting low-voltage power lines, streetlights, and distribution equipment.

Design Flexibility and Aesthetic Appeal

Tubular and tapered designs allow galvanized steel poles to be customized for specific project requirements. Their sleek appearance also enhances the visual appeal of urban and rural infrastructure projects.

Benefits of Using Galvanized Steel Utility Poles

1. Minimal Maintenance Requirements

Unlike wooden poles that require periodic treatment or concrete poles prone to cracking, galvanized steel poles need minimal maintenance. This significantly reduces operational costs over their lifespan.

2. Sustainability and Recyclability

Galvanized steel is 100% recyclable, making it an environmentally friendly choice for transmission line projects. At the end of their life cycle, the poles can be melted down and reused in other steel products.

3. Cost-Effectiveness for Low Voltage Transmission Projects

Although the initial cost of galvanized steel poles is higher than wood or concrete, their long-term durability and low maintenance needs make them a cost-effective solution.

Types of Low Voltage Galvanized Steel Utility Poles

| Type | Features | Applications |

|---|---|---|

| Tubular Steel Poles | Cylindrical shape, lightweight, and easy to manufacture. | Streetlights, low-voltage distribution lines. |

| Tapered Steel Poles | Wider base with a narrower top, offering better stability and load distribution. | Rural electrification, urban distribution. |

| Single Circuit Poles | Designed for one set of power lines, suitable for smaller projects. | Single low-voltage transmission lines. |

| Double Circuit Poles | Can support two sets of power lines, reducing infrastructure requirements. | Dual low-voltage power distribution projects. |

Manufacturing Process of Galvanized Steel Utility Poles

1. Steel Material Selection

High-quality steel is selected to meet the mechanical and structural requirements for low-voltage poles. The grade of steel is critical for ensuring strength and durability.

2. Shaping and Welding

Steel sheets are cut, rolled, and welded into tubular or tapered shapes. Advanced welding techniques ensure seamless joints that can handle high stress.

3. Hot-Dip Galvanizing

The poles are dipped into molten zinc to apply a uniform protective coating. This process ensures long-term corrosion resistance, even in harsh environments.

4. Quality Assurance and Standards

Every pole undergoes rigorous testing, including wind resistance, tensile strength, and coating thickness checks, to meet international standards like ASTM A123 and ISO 1461.

Applications of Low Voltage Galvanized Steel Utility Poles

1. Rural Electrification Projects

Galvanized steel poles are widely used in rural electrification programs due to their lightweight design and ease of installation. They can be transported to remote areas and erected with minimal equipment.

2. Urban Distribution Networks

In cities, low-voltage galvanized steel poles are used to distribute electricity to residential and commercial buildings. Their sleek design ensures minimal visual obstruction.

3. Street Lighting and Utility Distribution

Steel poles support streetlights and other utility lines, improving public safety and infrastructure reliability.

Technical Specifications of Low Voltage Galvanized Steel Poles

| Specification | Details |

|---|---|

| Height | 5 to 15 meters, depending on application. |

| Diameter | 300 to 500 mm at the base. |

| Wall Thickness | 3 to 5 mm, based on load requirements. |

| Wind Load Resistance | Up to 150 km/h, suitable for most environmental conditions. |

| Coating Thickness | 85 to 100 microns, ensuring long-term corrosion protection. |

| Load Capacity | 500 to 2,000 kg, depending on pole type and configuration. |

Comparison of Galvanized Steel Poles with Alternative Materials

| Feature | Steel Poles | Wooden Poles | Concrete Poles |

|---|---|---|---|

| Durability | 50+ years | 10–20 years | 30–40 years |

| Corrosion Resistance | Excellent | None | Moderate |

| Environmental Impact | Recyclable, low carbon footprint | Requires deforestation | Energy-intensive manufacturing |

| Maintenance | Minimal | High | Moderate |

Frequently Asked Questions (FAQs)

1. Why choose galvanized steel for low voltage utility poles?

Galvanized steel offers superior durability, corrosion resistance, and a long lifespan, making it ideal for low voltage utility poles.

2. How long do galvanized steel poles last in transmission lines?

These poles typically last 50+ years with minimal maintenance.

3. Can galvanized steel poles be customized for specific projects?

Yes, they can be customized in terms of height, diameter, coating thickness, and design to meet specific project needs.

4. What are the environmental benefits of using galvanized steel poles?

Galvanized steel is 100% recyclable and requires minimal maintenance, reducing resource consumption over its lifecycle.

5. Are these poles suitable for extreme weather conditions?

Yes, they are designed to withstand high winds, heavy loads, and other environmental stresses.

6. How do galvanized poles compare in cost to wood or concrete poles?

While the upfront cost is higher, the long-term savings on maintenance and replacement make galvanized steel poles more cost-effective.

Related posts

Hot Dip Galvanized Electrical Metal Utility Steel Pole for Railway in Shape Octagonal widely used in electrical power transmission railway station industry. In order to meet the increasingly higher demand for steel poles, our company design and produce many kinds of steel poles for the power transmission and distribution system. Besides, our electrical steel poles have been tested and approved by the Transmission Pole Tower Testing Station.