Analysis of the Bearing Capacity of Power Transmission Line Steel Tower

December 21, 2024

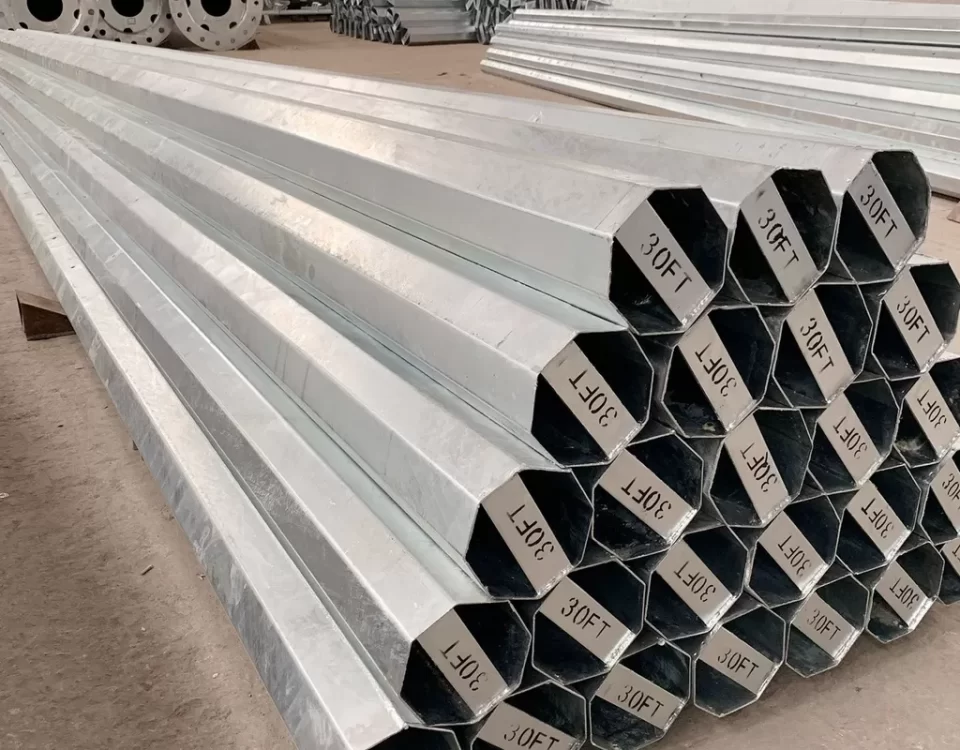

Polygonal Tubular Galvanized Steel Structural Electric Power Steel Pole

January 8, 2025Galvanized Steel Transmission Line Pole

Hot Dip Galvanized Electrical Metal Utility Steel Pole for Railway in Shape Octagonal widely used in electrical power transmission railway station industry. In order to meet the increasingly higher demand for steel poles, our company design and produce many kinds of steel poles for the power transmission and distribution system. Besides, our electrical steel poles have been tested and approved by the Transmission Pole Tower Testing Station.

Galvanized Steel Transmission Line Pole: Everything You Need to Know

Introduction to Galvanized Steel Transmission Line Poles

Galvanized steel transmission line poles are a vital component of modern infrastructure, providing the backbone for energy distribution and telecommunications systems. These poles are designed to support heavy loads, endure extreme weather conditions, and last for decades with minimal maintenance. Unlike traditional materials such as wood or concrete, galvanized steel offers superior durability, corrosion resistance, and cost-effectiveness, making it the material of choice for many utility companies and engineers worldwide.

Transmission line poles play a crucial role in ensuring the reliability of power distribution systems. Without them, it would be impossible to deliver electricity or communication signals over long distances. This article explores the importance of galvanized steel transmission poles, their benefits, manufacturing processes, and applications across various industries.

Importance of Transmission Line Poles in Power Infrastructure

Transmission line poles are essential for the efficient delivery of electricity from power generation plants to end users. They form the physical framework for:

- Power Transmission Lines: Supporting high-voltage cables for electricity distribution.

- Telecommunications: Hosting antennas and cables for cellular and internet services.

- Lighting: Supporting streetlights and other public infrastructure.

Advantages of Using Galvanized Steel for Transmission Poles

Durability and Longevity of Galvanized Steel

Galvanized steel poles are known for their exceptional lifespan, often exceeding 50 years with proper maintenance. The galvanization process involves coating the steel with a layer of zinc, which provides a robust barrier against rust and environmental degradation.

Corrosion Resistance Properties

Corrosion is one of the biggest challenges for outdoor infrastructure. Galvanized steel is specifically engineered to resist corrosion, even in highly saline or humid environments, making it ideal for coastal areas or regions with extreme weather.

Strength and Load-Bearing Capacity

Galvanized steel offers superior strength, enabling these poles to withstand high wind speeds, heavy snow loads, and other structural stresses. This makes them particularly suitable for high-voltage transmission lines and other demanding applications.

Types of Galvanized Steel Transmission Line Poles

Standard vs. Custom Design Poles

While standard poles are pre-designed for general applications, custom poles are tailored to meet specific project requirements such as height, load-bearing capacity, or environmental conditions.

Monopole Transmission Poles

Monopoles are single-column structures that occupy minimal space, making them ideal for urban areas where land availability is limited.

Multi-Pole Structures

For areas requiring higher load capacity or longer spans, multi-pole structures provide enhanced stability and performance.

Manufacturing Process of Galvanized Steel Poles

Steel Material Selection

The manufacturing process begins with the selection of high-quality steel, ensuring the material meets the structural and durability requirements.

Hot-Dip Galvanizing Process

The steel is dipped into a molten zinc bath during the galvanization process. This creates a strong, uniform coating that adheres to the steel surface, providing excellent protection against corrosion.

Quality Control Measures in Manufacturing

Each pole undergoes rigorous quality control checks, including tensile strength testing, coating thickness measurements, and visual inspections to ensure compliance with international standards.

Applications of Galvanized Steel Transmission Line Poles

High-Voltage Power Transmission

Galvanized steel poles are extensively used in high-voltage power lines to connect power plants with substations and distribution networks.

Telecommunications Infrastructure

In the telecom industry, these poles support cellular towers, antennas, and fiber optic cables, ensuring uninterrupted communication services.

Urban vs. Rural Applications

Urban areas benefit from the sleek, space-saving design of monopoles, while rural areas often utilize multi-pole structures for long-distance energy transmission.

Technical Specifications and Standards

| Specification | Details |

|---|---|

| Height | 10 to 60 meters, depending on application |

| Diameter | 300 to 1,000 mm at the base |

| Load Capacity | 1,000 kg to 10,000 kg |

| Coating Thickness | 85 to 100 microns |

| Wind Resistance | Up to 200 km/h |

| Lifespan | 50+ years with minimal maintenance |

Comparison Between Galvanized Steel Poles and Other Materials

| Material | Advantages | Disadvantages |

|---|---|---|

| Galvanized Steel | Durable, corrosion-resistant, long-lasting | Higher initial cost |

| Concrete | Low cost, stable | Heavy, difficult to transport |

| Wood | Affordable, renewable | Prone to decay, shorter lifespan |

Environmental and Economic Benefits of Galvanized Steel Poles

Galvanized steel poles are highly sustainable due to their recyclability and low environmental impact. They require minimal maintenance over their lifespan, reducing long-term costs and resource consumption.

Challenges and Limitations of Galvanized Steel Poles

Despite their many advantages, galvanized steel poles have some challenges, including higher initial manufacturing costs and transportation difficulties due to their weight and size.

Case Studies of Galvanized Steel Transmission Line Poles

- Urban Power Projects: Streamlining energy distribution in metropolitan areas.

- Rural Electrification Programs: Enhancing access to electricity in remote regions.

- Renewable Energy Grids: Supporting wind and solar power projects.

Frequently Asked Questions (FAQs)

- Why choose galvanized steel for transmission line poles?

Galvanized steel offers unmatched durability, corrosion resistance, and strength, making it ideal for transmission poles. - What is the lifespan of galvanized steel transmission poles?

These poles can last 50+ years with minimal maintenance. - How does galvanization prevent corrosion?

The zinc coating forms a protective barrier, preventing rust and environmental damage. - Are galvanized steel poles recyclable?

Yes, galvanized steel is 100% recyclable, contributing to sustainability. - What are the international standards for these poles?

Standards include ASTM A123 for galvanization and EN 40 for structural integrity. - How are these poles installed in remote areas?

Specialized equipment and modular designs facilitate installation in challenging terrains.

The Role of Innovation in Galvanized Steel Transmission Line Poles

The future of galvanized steel transmission line poles is bright, particularly as advancements in technology continue to improve their design, manufacturing processes, and applications. Innovation is helping engineers overcome the limitations of traditional designs while enhancing the performance, sustainability, and cost-efficiency of these structures.

Advanced Coating Technologies

One area of innovation lies in coating technologies. While traditional hot-dip galvanizing is effective, newer methods like duplex coating (galvanizing followed by a layer of paint or powder coating) are further extending the lifespan of poles, even in the most extreme environments.

Lightweight Designs

Engineers are exploring ways to reduce the weight of galvanized steel poles without compromising their structural integrity. Lightweight designs make transportation and installation more manageable, reducing overall project costs.

Integration with Smart Grids

Modern galvanized steel poles are being designed to integrate with smart grid technologies. This includes mounting sensors and communication equipment directly onto the poles, allowing for real-time monitoring of power lines and improved energy efficiency.

Modular and Pre-Fabricated Components

Modular designs are another game-changer. Prefabricated pole components can be assembled on-site, simplifying transportation and speeding up the installation process. This is particularly beneficial for projects in remote or inaccessible areas.

Installation Process for Galvanized Steel Transmission Line Poles

The installation of galvanized steel transmission line poles requires meticulous planning and execution to ensure safety and structural integrity. Below is a step-by-step overview of the process:

- Site Preparation

- Conduct soil testing to determine the load-bearing capacity of the ground.

- Clear the site of any obstructions and ensure proper leveling.

- Foundation Construction

- Excavate the area for the foundation based on the pole’s height and load requirements.

- Pour concrete to create a stable base for the pole.

- Pole Erection

- Use cranes or hydraulic equipment to lift the pole into position.

- Secure the pole to the foundation using anchor bolts.

- Cable Installation

- Attach power lines or communication cables to the pole using insulators and other accessories.

- Inspection and Testing

- Inspect the installation for alignment, stability, and compliance with safety standards.

- Perform load testing to ensure the pole can handle operational stresses.

Cost Analysis of Galvanized Steel Transmission Line Poles

Cost is a critical factor in the selection and use of galvanized steel poles for transmission lines. Below is a breakdown of the typical cost components:

| Cost Component | Details |

|---|---|

| Material Cost | High-quality steel and zinc for galvanization. |

| Manufacturing Cost | Includes cutting, welding, galvanizing, and quality control. |

| Transportation | Logistics costs for delivering poles to the project site. |

| Installation | Labor, equipment, and foundation expenses. |

| Maintenance | Minimal due to the durability of galvanized steel. |

While the initial cost of galvanized steel poles is higher than alternatives like wood or concrete, their long lifespan and low maintenance requirements make them more cost-effective in the long term.

Future Trends in Galvanized Steel Transmission Line Poles

The industry is poised for significant growth and transformation, driven by the increasing demand for efficient and sustainable infrastructure. Some key trends include:

- Integration with Renewable Energy Projects

- Galvanized steel poles are increasingly being used in wind and solar power projects, where they support high-voltage transmission lines connecting renewable energy sources to the grid.

- Focus on Sustainability

- With a growing emphasis on sustainability, the recyclability of galvanized steel is a significant advantage. Future designs may also incorporate more eco-friendly production processes.

- Digital Transformation

- The use of digital tools for designing and monitoring poles is gaining momentum. Advanced software allows for precise modeling and simulation, optimizing pole performance for specific applications.

- Urban Development

- As cities expand and modernize, the demand for sleek, space-saving monopoles will continue to rise. These poles are not only functional but also aesthetically pleasing, blending seamlessly into urban landscapes.

Key Accessories for Galvanized Steel Transmission Line Poles

To enhance their functionality and ensure safety, galvanized steel transmission line poles are often equipped with various accessories, including:

| Accessory | Purpose |

|---|---|

| Insulators | Prevent electrical leakage and support high-voltage cables. |

| Cross Arms | Provide additional support for multiple cables or conductors. |

| Anchor Bolts | Secure the pole to its foundation. |

| Climbing Ladders | Allow maintenance personnel to safely access the pole. |

| Lighting Fixtures | Used for poles that also serve as streetlights or area lighting. |

| Grounding Systems | Protect the pole and surrounding area from lightning strikes. |

Industry Insights and Market Trends

The global market for galvanized steel transmission line poles is experiencing steady growth, driven by increasing investments in infrastructure development and renewable energy. Some notable insights include:

- Geographic Growth

- Developing countries in Asia, Africa, and South America are investing heavily in rural electrification, boosting the demand for galvanized steel poles.

- Regulatory Frameworks

- Governments are enforcing stricter standards for corrosion resistance and structural integrity, further solidifying the preference for galvanized steel.

- Market Players

- Key manufacturers are focusing on innovation and expanding production capacities to meet rising demand. Partnerships with utility companies are also common.

Benefits of Investing in Galvanized Steel Transmission Poles

Utility companies and infrastructure developers benefit significantly from investing in galvanized steel poles. Key advantages include:

- Long-Term Reliability: Poles can last over five decades with minimal upkeep.

- Improved Safety: The strength of galvanized steel minimizes the risk of pole failure.

- Reduced Environmental Impact: Recyclability and low maintenance requirements make these poles environmentally friendly.

- Enhanced Performance: Superior load-bearing capacity and corrosion resistance ensure optimal performance under all conditions.

Conclusion: The Future of Galvanized Steel Transmission Line Poles

Galvanized steel transmission line poles represent the future of reliable, sustainable, and cost-effective infrastructure. Their unparalleled durability, minimal maintenance requirements, and adaptability to diverse applications make them a preferred choice for utility providers and engineers worldwide.

As innovation continues to refine their design and functionality, galvanized steel poles are set to play an even more critical role in powering modern societies. Whether supporting high-voltage power lines, telecommunications networks, or renewable energy grids, these poles are indispensable for building resilient and efficient infrastructure systems.

Related posts

In low-voltage transmission networks, which typically operate below 1,000 volts, galvanized steel poles provide a durable and environmentally friendly solution. This article explores the features, benefits, applications, and technical specifications of low voltage galvanized steel utility poles in transmission line projects.