Power Transmission Line Lattice Tower Comprehensive Technical Analysis

August 10, 2024

Tapered Tubular Steel Pole

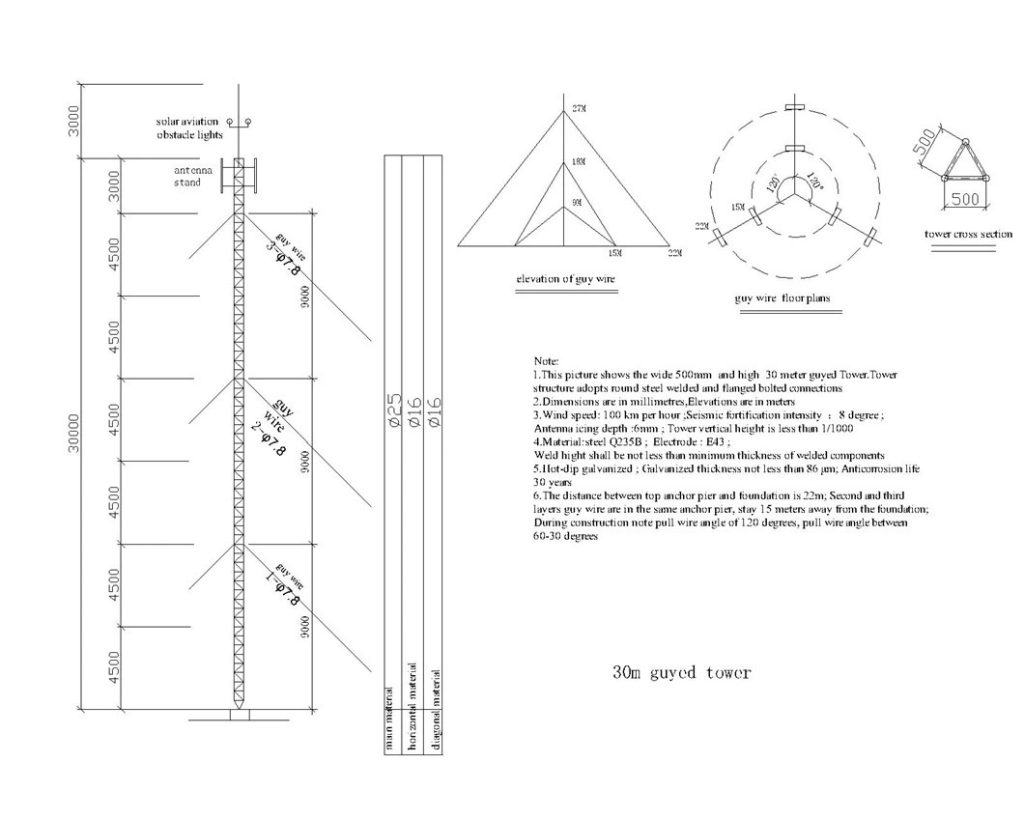

August 15, 2024Guyed Towers in Electrical Transmission Lines Life-Cycle Assessment of Foundations

Life-Cycle Assessment of Foundations for Guyed Towers in Electrical Transmission Lines

Introduction

The foundation of any structure is paramount to its stability and durability, and this is especially true for guyed towers in electrical transmission lines. These towers, often subjected to dynamic loads such as wind, ice, and seismic activity, require meticulously designed foundations to ensure their long-term performance and safety. This article delves into the life-cycle assessment (LCA) of foundations for guyed towers in electrical transmission lines, exploring various aspects such as material selection, environmental impact, cost considerations, and maintenance requirements.

Material Selection for Foundations

Concrete Foundations

Concrete is a widely used material for the foundations of guyed towers due to its strength and durability. Key attributes include:

- Compressive Strength: Concrete can withstand significant compressive forces, making it ideal for supporting heavy structures.

- Durability: Properly cured concrete can last for decades with minimal maintenance.

- Versatility: Can be molded into various shapes and sizes to accommodate different foundation designs.

Steel Reinforcement

Steel reinforcement is often used in conjunction with concrete to enhance its tensile strength. Features of steel reinforcement include:

- High Tensile Strength: Steel bars (rebars) provide the necessary tensile strength to the concrete foundation.

- Ductility: Steel’s ability to deform under stress without breaking adds to the overall resilience of the foundation.

- Corrosion Resistance: Galvanized or epoxy-coated rebars can resist corrosion, extending the lifespan of the foundation.

Composite Materials

Composite materials, such as fiber-reinforced polymers (FRPs), are emerging as alternatives to traditional materials. Advantages include:

- Lightweight: FRPs are significantly lighter than steel, reducing transportation and handling costs.

- High Strength-to-Weight Ratio: Offers excellent mechanical properties without adding excessive weight.

- Corrosion Resistance: Inherently resistant to corrosion, reducing long-term maintenance needs.

Environmental Impact

Carbon Footprint

The production of construction materials like concrete and steel has a substantial carbon footprint. Key considerations include:

- Cement Production: Cement manufacturing is a major source of CO2 emissions, accounting for approximately 8% of global emissions.

- Steel Production: Producing steel involves significant energy consumption and CO2 emissions, primarily from blast furnaces.

- Alternative Materials: Using recycled materials or low-carbon alternatives can reduce the environmental impact.

Land Use and Habitat Disruption

The construction of foundations for guyed towers can disrupt local ecosystems. Important factors include:

- Site Preparation: Clearing land for construction can lead to habitat loss and soil erosion.

- Biodiversity Impact: Construction activities can affect local flora and fauna, potentially leading to a loss of biodiversity.

- Mitigation Measures: Implementing measures such as reforestation or creating wildlife corridors can help mitigate these impacts.

Cost Considerations

Initial Construction Costs

The initial cost of constructing foundations involves several factors:

- Material Costs: Concrete, steel, and composite materials have varying costs, impacting the overall budget.

- Labor Costs: Skilled labor is required for tasks such as excavation, formwork, and concrete pouring.

- Equipment Costs: Heavy machinery, such as cranes and concrete mixers, adds to the initial construction costs.

Maintenance Costs

Maintenance is a critical component of the life-cycle cost of foundations. Key points include:

- Inspection and Monitoring: Regular inspections are necessary to identify and address potential issues such as cracks or corrosion.

- Repair and Rehabilitation: Over time, foundations may require repairs or reinforcement to maintain structural integrity.

- Preventive Measures: Implementing preventive measures, such as applying protective coatings, can reduce long-term maintenance costs.

End-of-Life Costs

At the end of their service life, foundations may need to be decommissioned. Considerations include:

- Demolition Costs: The cost of demolishing and removing the foundation materials can be significant.

- Recycling and Disposal: Proper disposal or recycling of materials, such as concrete and steel, is necessary to minimize environmental impact.

- Site Restoration: Restoring the site to its original condition or repurposing it for other uses can also incur costs.

Maintenance Requirements

Regular Inspections

Regular inspections are essential to ensure the continued safety and performance of the foundations. Key aspects include:

- Frequency: Inspections should be conducted at least annually, with more frequent checks in high-stress environments.

- Scope: Inspections should cover all aspects of the foundation, including visible cracks, signs of settlement, and corrosion of steel components.

- Documentation: Keeping detailed records of inspections and maintenance activities is crucial for tracking the condition of the foundation over time.

Preventive Maintenance

Preventive maintenance can extend the life of foundations and reduce the need for costly repairs. Strategies include:

- Protective Coatings: Applying coatings to protect against moisture and chemical exposure can prevent corrosion and degradation.

- Drainage Systems: Ensuring proper drainage around the foundation can prevent water accumulation and soil erosion.

- Vegetation Control: Managing vegetation around the foundation can prevent root growth from damaging the structure.

Repair and Rehabilitation

When issues are detected, timely repairs are necessary to maintain the integrity of the foundation. Key considerations include:

- Crack Repair: Sealing cracks in concrete can prevent water ingress and further deterioration.

- Steel Reinforcement Repair: Replacing or reinforcing corroded steel components can restore the foundation’s strength.

- Grouting and Underpinning: Techniques such as grouting and underpinning can stabilize foundations that have experienced settlement or shifting.

Conclusion

The life-cycle assessment of foundations for guyed towers in electrical transmission lines encompasses a comprehensive evaluation of material selection, environmental impact, cost considerations, and maintenance requirements. By understanding and addressing these factors, we can design and construct foundations that not only support the structural integrity of the towers but also minimize environmental impact and optimize long-term costs. Through regular maintenance and timely repairs, the lifespan of these critical infrastructure components can be extended, ensuring the reliable transmission of electrical energy for years to come.

Meta Description

Explore the life-cycle assessment of foundations for guyed towers in electrical transmission lines, covering material selection, environmental impact, cost considerations, and maintenance requirements for sustainable and durable infrastructure.