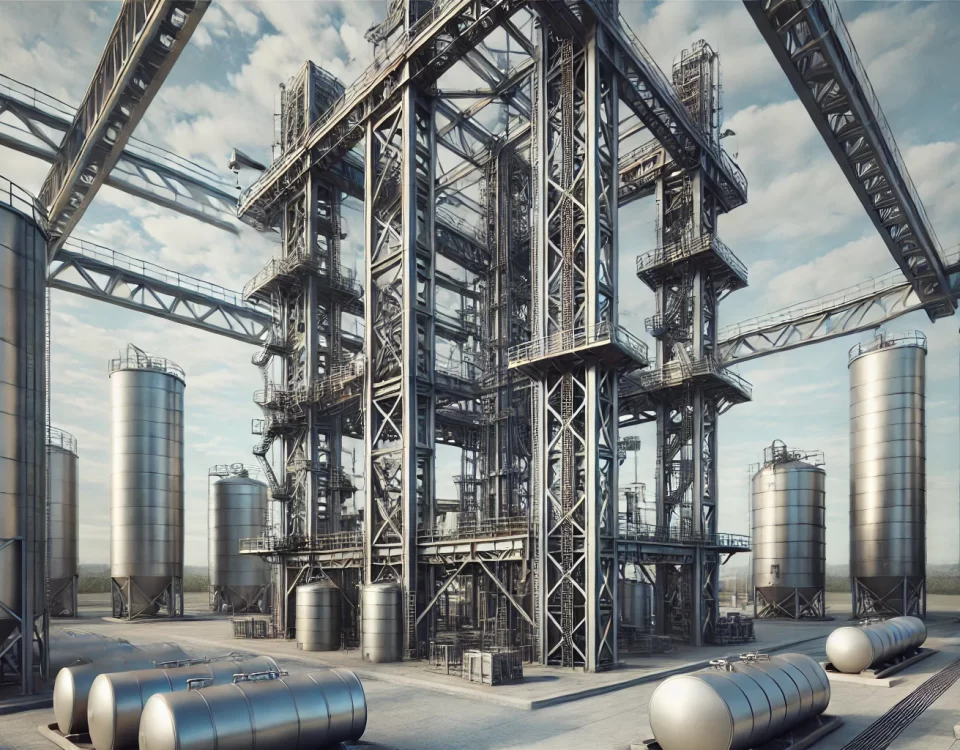

Lattice towers have been around the block for decades, though there has been a huge spotlight on them in recent years. While high demand in Africa is keeping the balance sheets of manufacturers healthy, it also places the onus on them to deliver products of best possible quality to enable the clients to deliver the best services in power and telecommunications.

Power transmission

In power transmission, three and four legged angular lattice towers are most common. Typically, as standard, they come with cat and cable ladders, internal working and resting platforms with safety rails, aircraft warning lights, antenna brackets, down conductor, foundation holding down bolts and template.From Rooftop, BTS, Rapid Deployment, Backbone to High Site, Fencing to enclose your sites, and of course we will design the foundations required.

A development that one cannot fail to notice in South America is the exponential growth in the market for hot dip galvanized steel lattice towers, over the past two decades. Mainly, this has been driven by the high demand in the power transmission and telecommunications sectors. Hot dip galvanized angle steel towers (lattice towers) are the common choice in high voltage transmission lines (sometimes they are also used in other voltages), while self-supporting steel lattices are preferred in wireless telecommunications (cellular and microwave networks). Albeit on a small scale, there is also demand for hot deep galvanized steel lattice towers in the wind energy market in South America, as part of the country’s drive to use clean energy sources.

Power Transmission Steel Tower could be fabricated as per GB, EN or ASTM standard with high quality.

Technical Data

The design of Power Transmission line tower depends on, type of conductor and Earth-wire, wind zone, deviation angle and material specification. These towers are galvanized to protect the steel from corrosion. The galvanizing coating thickness depends on the weather conditions at the location of tower.

|

Design

|

|

1. Voltage grade

|

330KV

|

|

Structure Steel

|

|

|

High Tensile Steel

|

Mild Steel

|

|

2. Grade

|

GB1591: Q345B, Q345C,Q3455D

|

GB700: Q235B, Q235C,Q235D

|

|

EN10025:S355JR, S355J0, S355J2

|

EN10025:S235JR,S235J0,S235J2

|

|

ASTM A572 Gr50

|

ASTM A36

|

|

3. Tension strength (Mpa)

|

470~630 Mpa

|

360~510 Mpa

|

|

4.Yield strength (t≤16mm) (Mpa)

|

355 Mpa

|

235 Mpa

|

|

5. Elongation (%)

|

20

|

24

|

|

6. Sharpy V-notch Test

|

27J(20°C)

|

Q345B/S355JR

|

27(20°C)

|

Q235B/S235JR

|

|

27(0°C)

|

Q345C/S355J0/A572 Gr50

|

27(0°C)

|

Q235C/S235J0/A36

|

|

27(-20°C)

|

Q345D/S355J2

|

27(-20°C)

|

Q235D/S235J2

|

|

Bolts & Nuts

|

|

7. Grade

|

Grade 4.8, 6.8, 8.8

|

|

8. Standards for mechanical properties

|

|

8.1 Bolts

|

ISO 898-1

|

|

8.2 Nuts

|

ISO 898-2

|

|

8.3 Washers

|

ISO 6507-1

|

|

9. Standards for Dimensions

|

|

9.1 Bolts

|

DIN7990/DIN931/DIN933

|

|

9.2 Nuts

|

ISO4032/ISO4034

|

|

9.3 Washers

|

DIN7989/ DIN127B/ISO7091

|

|

|

|

|

Marking

|

|

10. Method of marking of the members

|

Hydraulic Press Stamping

|

|

Welding

|

|

11. Method

|

CO2 Shielded Arc Welding & Submerged Arc Welding(SAW)

|

|

12. Standard

|

AWS D1.1

|

|

Galvanizing

|

|

13. Galvanization standard of steel sections

|

ISO 1461 or ASTM A123

|

|

14. Galvanization standard of bolts and nuts

|

ISO 1461 or ASTM A153

|

|

Capacity

|

|

15. Maximum Production Capacity of Steel Tower per annum

|

100,000 TON per annum

|

|

16. Maximum Capacity of Galvanizing Plant per annum

|

100,000 TON per annum

|

|

Test

|

|

17. Factory test

|

Tensile test, Elements analysis, Sharpy V-notch test(impact test), Cold Bending, Preece test, Hammer test

|

|

18. Type test

|

Type Test(IEC 60652:2002)

|

| |

|

|

|

|

|

We are one of leading professional manufacturer in galvanized electrical angle steel tower for transmission tower line,telecommunication tower, substation/railway steel structure.The products we fabricated is mainly involved in steel tower, steel pole, galvanized electrical angle steel tower for transmission tower line, telecommunication tower, lattice tower, microwave tower, mono pole, antenna tower, angular/angle tower, street light pole, tv and radio tower, cross tower,substation/railway steel structure and related steel structure.

Transmission Line Steel Tower

What gives the angle lattice tower the edge

Compared with self-supporting lattices, there should be no doubt why angle lattice towers are the most preferred in power transmission projects for a number of advantages, main in terms of modelling and design, fabrication, transportation and erection.

Modeling and designing of angle lattice towers is relatively easy. In addition, they can be easily configured to accommodate several electrical circuits and and various conductor configurations.

With a quick factory set up, angle lattice towers are easy to fabricate, at a significantly cost at that. Furthermore, they are easier to galvanize.

Lattice towers take the worry out of transportation, as they can be accommodated by the capacity of the available truck. Moreover, the sizes and weights that can be transported are considerably less than tubular steel poles.

Working with angle lattice towers provides for extremely flexible scheduling on a building site, with many jobs of work performed parallel.

The market

While, directly or indirectly, other sectors have been affected by the low commodity prices, there is no letup in demand for infrastructure for power transmission and telecommunications in South America countries. Project tenders in these areas are being released by both governments and the private organizations with hundreds of millions to spend, a development which should raise optimism amongst manufacturers of lattice towers.

Key requirements

The fact of the matter is that customers located in most parts of Africa, where the road infrastructure is in a state of disrepair or non-existent, need products as soon as possible. Understandably, any delay might result in the escalation of project costs. In the main, the three critical things which clients need turnkey convenience and they are also particular about quality as the products are meant to be used for delivery of vital service to millions in countries.

Turnkey convenience is a pre-requisite for most organizations. Clients working on tight budgets and looking forward to delivering would rather deal with a company that has the resources to design, manufacture, pack and transport to a country where they are needed, on time, to the expected quality and quantity. The scope of services cover: Rooftop, BTS, Rapid Deployment, Backbone to High Site, and sometimes fencing to enclose site.

Noteworthy, considering the time constraints which they face and the pressure to deliver a service, rapid deployment, which does not need permanent concrete foundations, has become a popular option.

-

Quality (product standards)

Once in a while, the issues of quality of steel lattice towers always surface as products from other parts of the world are flooding the local market. However, fortunately, most manufacturers from South Africa who supply African countries are under strict obligation to follow Lattice Tower Specifications Design Specifications that are in keeping with the South African Bureau of Standards (SABS 0162 Part 1 1991 and SABS 0160 Part 1 1998). These cover areas such as: Mass of Tower, Mass of cat ladder, Maximum forces (Per leg), Site altitude, Design and survival wind speeds, Mean wind return, Artificial base height, Antenna, cat ladder, feeder and tower loading area.