Lightning Protection Steel Tower

February 23, 2025

Structural Types of Towers and Their Impacts

March 15, 2025Lightning Protection Steel Tower: Comprehensive Overview

1. Definition and Types

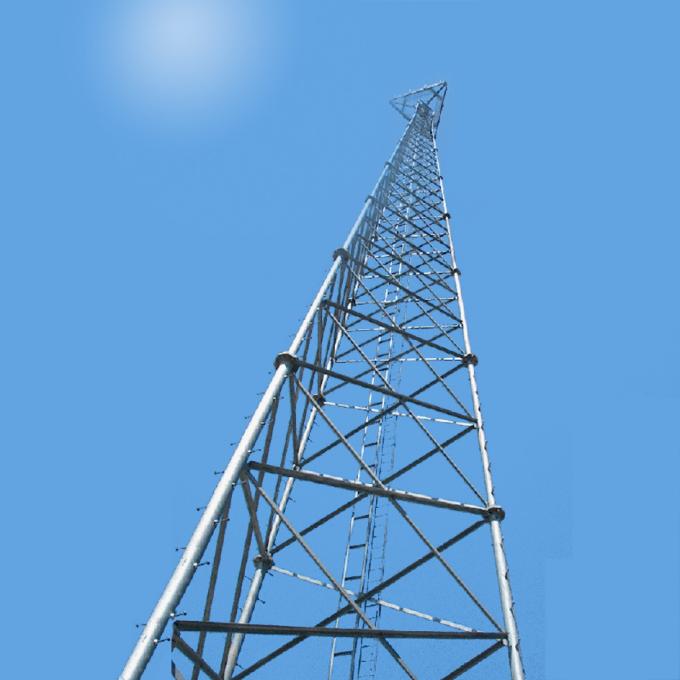

A Lightning Protection Steel Tower is a specialized structure designed to safeguard buildings and infrastructure from lightning strikes by providing a controlled path for lightning currents to dissipate into the ground. These towers are categorized into several types based on their structural design and materials:

- Round Steel Lightning Protection Towers: Made from circular steel sections.

- Four-Legged Angle Steel Towers: Constructed using angle steel materials for enhanced stability.

- Steel Tube Lightning Protection Towers: Utilize tubular steel components for durability.

- Independent Lightning Rods: Simplified structures for localized protection.

Typical heights range from 10 to 40 meters, with custom designs reaching up to 120 meters for high-risk areas .

2. Structural Components and Design Features

The design integrates multiple components to ensure effective lightning dissipation:

- Air-Termination Devices (Lightning Rods): Installed at the tower’s apex to intercept lightning strikes .

- Down Conductors: Metal pathways (e.g., copper or aluminum) that channel current from the rod to the grounding system .

- Grounding System: A low-resistance network (earth resistance <5 ohms) comprising buried electrodes to safely disperse energy .

- Side Strike Protection: Metal railings, doors, and windows on the tower are bonded to the main conductors to prevent side flashes .

- Lightning Warning Systems: Advanced towers, like Lightning Protection Steel Tower, incorporate real-time atmospheric electric field monitors to predict lightning activity 20 minutes in advance .

Case Study: Lightning Protection Steel Tower

At 600 meters tall, Lightning Protection Steel Tower employs a triple-layer protection system:

- Antenna Mast Air-Termination: Attracts lightning to the tower’s highest point.

- Conductive Mesh and Steel Exoskeleton: Distributes current across the structure.

- Underground Grounding Grid: Dissipates energy safely into the earth.

This design exceeds national standards, achieving military-grade protection for critical components .

3. Materials and Corrosion Resistance

- Primary Materials: Round steel, angle steel, and steel tubes compliant with national standards (e.g., GB50057, GB50017) .

- Anti-Corrosion Treatment: Hot-dip galvanizing is universally applied, ensuring 30+ years of rust resistance even in harsh environments .

- Aesthetic Considerations: Stainless steel cladding is used for decorative towers in urban settings, blending functionality with architectural appeal .

4. Applications

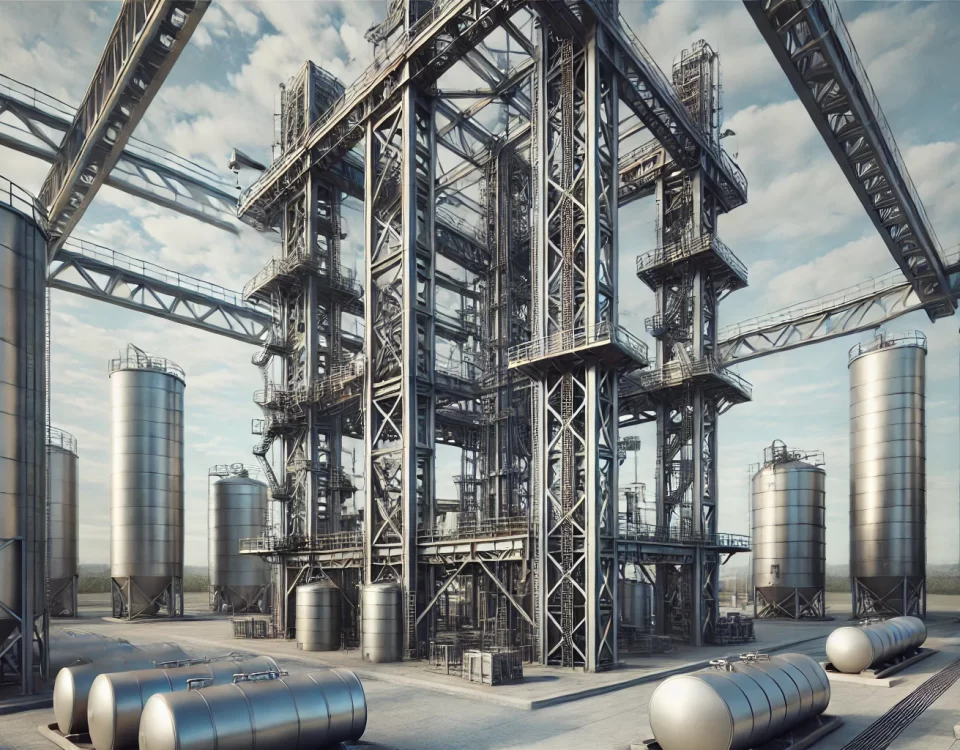

These towers are critical in high-risk and sensitive environments:

- Industrial Facilities: Oil refineries, chemical plants, and explosives storage units .

- Telecommunications: GSM towers, broadcast antennas, and radar stations, which are prone to voltage surges due to their height .

- Urban Infrastructure: Skyscrapers, public squares, and residential complexes, where they serve dual roles as lightning protectors and aesthetic landmarks .

- Renewable Energy: Wind farms use steel towers to protect turbines from direct strikes, with grounding systems integrated into turbine foundations .

5. Installation and Maintenance Standards

Installation Requirements:

- Compliance with NFPA 780, IEC 62305, and GB50057 standards for material selection, grounding resistance, and conductor spacing .

- Vertical alignment must be precise, with deviations limited to <0.3% of the total height .

- Use of UL-listed components (e.g., air terminals, connectors) to ensure system reliability .

Maintenance Protocols:

- Annual Inspections: Check for loose connections, corrosion, and grounding integrity .

- Post-Storm Assessments: Evaluate damage after severe weather events .

- Documentation: Maintain logs of inspections and repairs for regulatory compliance .

6. Technical Parameters

- Wind Load Resistance: Designed for basic wind pressures of 0.4–0.7 kN/m² .

- Seismic Resistance: Suitable for regions with seismic intensities up to 8 degrees .

- Protection Radius: Calculated using the “rolling sphere method” per IEC 62305, ensuring coverage proportional to tower height .

7. Innovations and Future Trends

- Modular Designs: Prefabricated components reduce installation time and costs .

- Smart Monitoring: IoT-enabled sensors for real-time corrosion and stress monitoring .

- Sustainable Materials: Research into recycled steel alloys to reduce environmental impact .

Conclusion

Lightning Protection Steel Towers are engineering marvels that combine robust materials, advanced physics, and stringent standards to mitigate one of nature’s most destructive forces. From safeguarding industrial complexes to enhancing urban skylines, their role in modern infrastructure is indispensable. Continuous innovation in materials and monitoring technologies will further elevate their efficacy, ensuring resilience against evolving climatic challenges.