Lightning Protection Steel Tower

Definition of Lightning Protection Steel Tower

A lightning steel tower is a tower device used to protect buildings from lightning disasters. It is usually composed of tower bodies, platforms, ladders, antenna support, lightning rods, flashers, feeder brackets and grounding conductors. The material of the lightning protection steel tower is generally Q235 steel. It has been hot-dip galvanized and has good corrosion resistance and a service life of more than 30 years. The height of the lightning protection steel tower is usually between 10 meters and 40 meters, and the tower height required by special design can reach 120 meters.

The lightning protection principle of lightning protection steel towers is to introduce lightning into the ground through metal conductors, thereby protecting buildings, their internal equipment and personnel from lightning damage. The design and installation of lightning protection steel towers must comply with the national standards “Building Lightning Protection Design Code”, “Heighth Structure Design Code”, “Mast Tower Construction and Acceptance Regulations”, etc. Lightning protection steel towers are not only used in high-risk areas such as oil refineries, chemical plants, coal mines, etc., but are also widely used in communication base stations, radio and television towers, microwave communication towers, etc.

The grounding system of the lightning protection steel tower is an important part of it, ensuring that lightning current can be safely introduced to the ground. The grounding system includes a grounding body, a grounding wire and a grounding resistor, and the grounding resistance should be less than 5 ohms. In addition, during the installation of the lightning protection steel tower, attention should be paid to factors such as wind, rain and snow weather and visibility to ensure construction safety.

In short, lightning protection steel tower is an efficient and reliable lightning protection device, which is widely used in various high-risk areas and important buildings, effectively reducing losses caused by lightning disasters.

Structural components and design features of Lightning Protection Steel Tower

The lightning protection system of jielian Lightning Protection Steel Tower has the following structural components and design features:

- Flash connection device : A lightning protection flash connection device is installed on the antenna mast, which uses its metal structure to attract lightning and guide it to the tower, thereby protecting the surrounding area from lightning strikes.

- Lightning protection grid : A lightning protection grid is designed on the top of the tower body, and together with the tower metal steel outer cylinder and the grounding grid at the bottom of the tower form a lightning conductive line. Lightning protection grids capture lightning quickly and accurately and direct them to the ground.

- Conducting circuit : The lightning protection grid, the tower body metal steel outer cylinder and the tower bottom grounding grid together form a lightning conductive circuit. When the flash connection device is attracted by lightning, the current can be transmitted to the metal steel outer cylinder of the tower body through the lightning protection grid, and then transmitted to the ground through the ground grid at the bottom of the tower to ensure that the lightning energy is released quickly and does not cause damage to the tower body.

- Grounding system : The grounding grid at the bottom of the tower is connected to the ground to form a closed loop to ensure that the lightning current can be safely discharged to the ground. The grounding system is designed to comply with national standards to ensure that the grounding resistance meets the requirements.

- Electronic equipment protection : The electronic equipment in the tower has taken measures such as grounding, shielding, and installing surge protectors to resist the impact of lightning, electromagnetic pulse interference.

- Lightning protection warning system : Lightning Protection Steel Tower is also equipped with an advanced atmospheric electric field instrument lightning warning system, which can conduct thunderstorm detection and early warning 20 minutes before lightning occurs, further improving the safety of the tower.

- Material selection : The tower body is made of Q235-Q420 high-quality carbon structural steel, which is hot-dip galvanized to prevent corrosion, ensuring its durability and safety in harsh climate conditions.

- Design Standards : The lightning protection design of Lightning Protection Steel Tower exceeds the existing building lightning protection technical standards and adopts best practices in international and domestic standards to ensure the safety and reliability of the tower.

To sum up, the lightning protection system of Lightning Protection Steel Tower ensures that the tower is in thunderstorm weather through the comprehensive use of flash connection devices, lightning protection grids, conductive lines, grounding systems, electronic equipment protection and lightning protection early warning systems. Run safely.

Materials used in Lightning Protection Steel Tower construction

The materials used in the construction of lightning protection steel towers in Lightning Protection Steel Tower mainly include the following types:

- Steel : The tower body, antenna mast, lightning protection grid, bottom grounding grid of Lightning Protection Steel Tower are all made of steel. These steels are hot-dip galvanized to prevent corrosion, ensuring that they can effectively conduct current during lightning strikes and protect the safety of buildings and personnel.

- Copper or aluminum : Lightning flashing devices (such as lightning rods) are usually made of copper or aluminum, which have good conductivity and can effectively introduce lightning current to the ground.

- Anti-corrosion treatment : After processing, steel will be hot-dip galvanized to prevent rust and ensure its long-term use effect.

- Composite materials : In some cases, composite materials may be used as part of the lightning protection system, but the main materials are still steel and metal.

- Other metal components : Metal railings, metal doors and windows, glass curtain walls on each floor of the tower body are also connected to the tower body lightning protection device to ensure that current can be directed to the ground.

To sum up, the construction of lightning protection steel towers in Lightning Protection Steel Tower mainly uses steel, copper or aluminum and other materials, and the lightning protection effect is ensured through hot-dip galvanizing treatment and anti-corrosion measures.

Applications and use cases of Lightning Protection Steel Towers

The application and use cases of lightning protection steel towers are widely used, mainly including the following aspects:

- Communication tower : Lightning protection steel towers are very common in communication towers and are used to protect communication equipment such as base stations and antennas from direct lightning strikes and induction lightning. These towers are usually made of Q235 steel, which has good conductivity and corrosion resistance, and can effectively guide lightning current and safely guide it to the ground.

- Radio and Television Tower : Radio and Television Tower is one of the important application areas of lightning protection steel tower. These towers need not only protect the tower body itself, but also the antennas and other electronic devices on the tower. Lightning protection systems usually include flash connectors, lead wires and grounding devices to ensure that lightning current can be discharged quickly and safely.

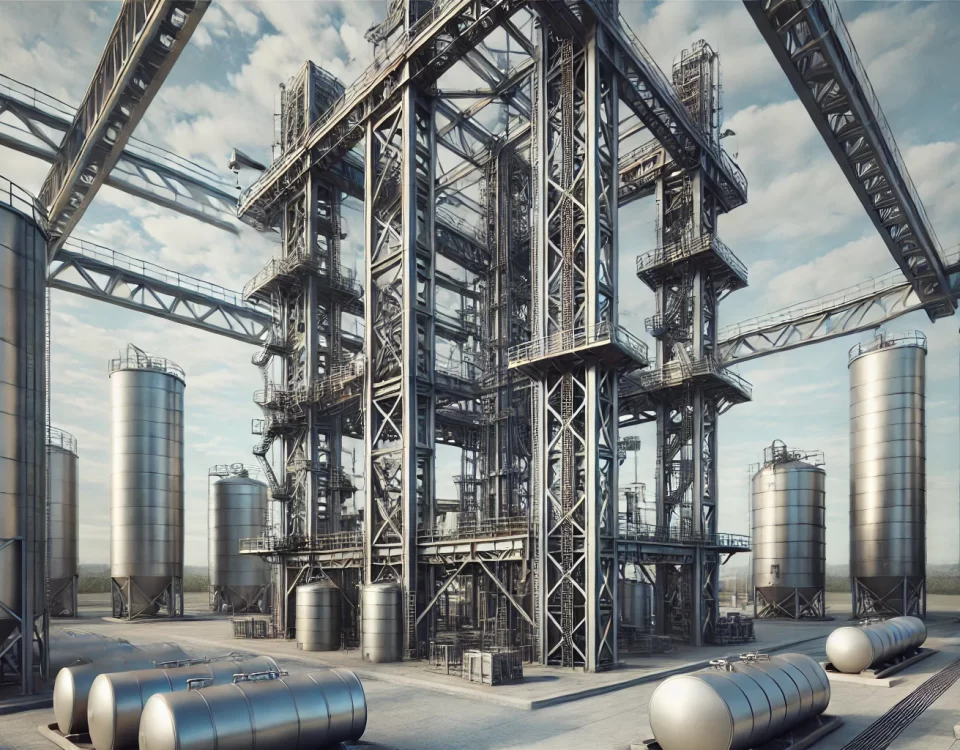

- Petrochemical facilities : In high-risk places such as petrochemical, natural gas, and chemical industries, lightning protection steel towers are used to protect storage tanks, pipelines and other key equipment. These towers are usually hot-dip galvanized to improve corrosion resistance and conductivity and ensure the safety of equipment in thunderstorms.

- Coal mines and flammable and explosive places : In flammable and explosive places such as coal mines, chemical factories, gas stations, etc., lightning protection steel towers are used to protect these places from direct lightning strikes and induction lightning. These towers must be designed and installed in compliance with strict lightning protection standards to ensure the safety of equipment and personnel during thunderstorms.

- Wind power tower : Wind power towers are an important part of the modern energy field, and lightning protection steel towers are used to protect wind turbines and towers from lightning damage. These towers usually have steel tubular structures, which have good conductivity and corrosion resistance, and can effectively guide lightning currents and safely guide them to the ground.

- Military facilities : The lightning protection steel tower in military facilities is used to protect radar stations, communication stations and other key equipment. The design and installation of these towers must comply with strict military lightning protection standards to ensure the normal operation of equipment and the safety of personnel during thunderstorms.

- Urban landscape architecture : In modern cities, many high-rise buildings and landscape buildings also use lightning protection steel towers. These towers not only have lightning protection functions, but also have beautiful designs, making them iconic buildings in the city.

- Monitoring tower : Monitoring towers are widely used in areas such as urban safety and traffic monitoring. Lightning protection steel towers are used to protect monitoring equipment from lightning damage and ensure the continuous operation of the monitoring system.

In short, lightning protection steel towers play an important role in many fields, and through effective lightning protection design and installation, the safety of buildings, equipment and personnel is ensured.

Installation and maintenance requirements for Lightning Protection Steel Towers

The requirements for installing and maintaining lightning protection steel towers are as follows:

- Installation requirements :

- Lightning protection systems should comply with national standards such as NFPA 780, UL 96 and UL 96A.

- The steel tower should be made of stainless steel to improve corrosion resistance and wind resistance.

- Lightning protection system should include a flash connector (such as a lightning rod), a lead wire and a grounding device.

- The flash connector should be installed at the highest point of the steel tower, such as the top of the tower, to attract lightning and guide it to the ground.

- The grounding device should be made of copper or aluminum to ensure a low resistance path to safely ground the mines.

- All metal components, such as the frame of the steel tower and the equipment housing, should be connected to the lightning protection system to form a continuous conductive path.

- Maintenance requirements :

- Regularly check the integrity and functionality of the lightning protection system to ensure that all connection points and flash connectors are not loose or damaged.

- Sense the ground resistance to ensure it is below 25 ohms.

- For structures over 75 feet (23 meters) tall, Class II material should be used.

- Regular electrical continuity tests are performed to ensure reliable electrical connections between all components.

- Follow the operating and maintenance manuals provided by the manufacturer to ensure the long-term and effective operation of the system.

- Special Requirements :

- The lightning rod and lead wire of the steel tower should be made of UL certified materials.

- The grounding system should adopt a combination of a horizontal grounding body and a vertical grounding body to ensure the grounding effect.

- The design and installation of lightning protection systems should be done by experienced professionals to ensure compliance with all relevant standards and specifications.

By following the above requirements, the safety and effectiveness of the lightning-proof steel tower can be ensured, and personnel and equipment can be protected from lightning damage.