HV 66KV Transmission Line Tower Material Specification

December 27, 2018

general information about guyed lattice mast,guyed lattice towers and masts

January 10, 2019necessary parts of Radio masts and towers,communication towers

- Steel Work

- The steel used in the fabrication of the tower shall comply with BS, JIS or an equivalentstandard proposed by TowerSupplier and agreed by “*****”.

- The slenderness ratio, l/r, of a member in compression shall not exceed:

- 150 for main members

- 200 for secondary members

- 240 for other members

Members used solely to reduce the effective length of chords and main bracing shall, together with their connectors, be capable of carrying loads equal to 1% of the load in the primary members being supported, or the member should have maximum effective slenderness ratio (l/r) of 240, whichever condition is more stringent.

- Notwithstanding the stress involved, no member of a structure shall be less than 6mm (Six) in thickness.

- Allowable tolerance shall be as follows

- +/- 0.75mm for location of centers of holes

- +/-1.5 mm for overall length of members

- +/-1.5mm for bolt holes

- Opening of any holes shall not be carried out after galvanizing.

- All members, before being assembled, shall be straight, unless required to be curvilinear formand shall be free from twist. For the purpose of the specification, “straight” shall mean freefrom kinks and from gradual bends greater than 1/1000 of member length. Members on sitenot meeting this condition will be reworked or replaced. Lengths of all members shall beaccurate so that when assembled no sagging or twist occurs

- No members of the tower shall have any joint by means of welding.

- All steel shall have numbers of identification marks on the steel together with manufacturer’scertificate receiving such numbers or marks, showing that the steel has been tested andcomplies with all tests and requirements of the relevant standard and grade of steel.

- Steel shall at all stages of fabrication be identifiable by grade and by an appropriate colormarking or other marking method.

- Member Identification Notations shall be clearly marked on each and every member and the Member notation shall not be unclear after the galvanizing process and/or painting.

- Drawings of all steel parts including tower structural parts detail methods of assembly and list of items shall be provided

- Standard Dimensions:

The standard dimensions, form, weight, tolerances, etc. of all structural hot rolled or cold for med sections shall conform to the following standards

- Hot – Rolled Sections: BS 4, Part 1: 1969 “Hot Rolled Hollow Sections”

- Hot – Rolled Hollow Sections: BS4, Part 2: 1969 “Hot Rolled Hollow Sections”

- Cold Formed Sections: BS 2994: 1976 “Cold Rolled Steel Sections”

- Fabrication

- All fabrication and identification of structural steel shall conform to AISCspecifications

- A representative from the “****”shall have access to all reasonabletimes to all places where the work is being carried out.

- In particular, the steel should not be subjected to excessive cold working, severmechanical damage or severe heating / cooling cycles. Steel may be hot bent afterheating at temperatures up to 650 °C but shall be allowed air – cool after heating andshall not be cooled with water.

- All oxygen cut surfaces shall have an average height of irregularities of not morethan 0.025mm. Roughness exceeding this value, and occasional notches and gaugesnot more than 5mm deep on otherwise satisfactory surfaces, shall be removed bymachining or grinding. Correction of defects shall be faired to the oxygen cut surfacewith slope not exceeding 1 in 10.

- Re-entrant corners shall be shaped notch – free to a radius of at least 12mm, unlessspecifically noted otherwise on the drawings.

- Bolts, Nuts and Washers

- Nuts and heads of bolts shall be of the hexagonal type.

- Bolts and nuts shall be in accordance with latest BS, JIS or as specified by Tower Supplier andagreed by the “*******”.

- Bolts and nuts shall be hot dip galvanized. Thickness of galvanization shall be more than 350g/m2

- To ensure that the full bearing areas of blots are developed, the thread portion of the boltsshall not extend within the thickness of members being jointed.

- All bolts or screws shall be fitted with spring washers or retaining nuts of approved design.Spring washers or retaining nuts shall be galvanized by the hot dip process and shall be fullyeffective after galvanizing. Zinc plating will not be accepted as a substance for galvanizing.

- A positive means of distinguishing high tensile bolts from mild steel bolts shall be provided Tower Supplier shall state the method of identification proposed. After tightening the threadedportion, each bolt shall project through the nut by at least two threads, but the length of theprojection shall not exceed 60% of the bolt diameter.

- Locking nuts for the leg anchoring shall have minimum two (02) nuts and exposed part tohave minimum ten (10) threads. Locknuts shall provide for each and every “U” or “V” bolts.

- The Tower Supplier shall provide bolts & nuts, and lock washers in a quantity in excess of the actualbolt count, of each size required for each tower site.

- During the tightening operation the bolt head shall be prevented from rotating. No painting ofthe bolts or washers shall be carried out without the prior approval. In all other respects ofbolts and nuts in the relevant clauses of BS 3294 part I shall be adhered to.

- Platforms

- Platform to provide safe working conditions shall be designed at each level of self-supporting tower where planned and future antenna and aircraft warning light are fitted.

- The rest platforms shall be provided so that the interval between any two adjacent platformsdoes not exceed fifteen (15) maters.

- Platforms shall be designed to take stationary and moving load of 4 person plus equipmentweighing 100kg.

- At each platform shall be provided with “Toe-plates”

- Inner platforms with 1.5m inside and outside projections shall be provided at the heights of40m, 70m, 90m and110m an indicated in the ‘General Requirements’.

- Working platforms complete with handrails to provide safe working areas.

- A resting platform to be provided.

- Tower Supplier needs to supply a circular top working platform according to the “******” requirement. Further this would be extended with cellular brackets if requested bythe “******”.

- Cellular brackets to be supported by channel section, which is mounted to tower legs andplatform mesh to be provided by expanded metal, fabricated grid.

- Platform decking shall be expanded metal, fabricated grid or a similar material, adequately supported by steel members of appropriated size.

- Handrails

- Handrails at a height of One (1) meter, intermediate rails at half meter above the decking andkick rail on the decking.

- The handrail and kick rail for antenna supporting tower shall be rolled steel angle sections ofdimensions not less than 5cm x 5cm x0.5cm.

- Handrails shall be provided as far as they are consistent with access to the antennas andaircraft warning lights, and shall encompass the ladder and the ladder guard so that freeaccess to the ladder may be gained from the platform.

- Handrails on working platform shall not be structural member and shall be removable tofacilitate the mounting of antenna. Above railing specifications are same for extendedbrackets also.

- Antenna Mounting

- Tower shall be complete with antenna mounting steel work to which the antenna may berigidly attached by means of the mounting hardware supplied a part of the antenna system.Means for adjusting antennas direction in both elevation and azimuth shall be provided.

- Details of the antenna mounting steel work shall be included in Tower Supplier technical proposal.

- At the top of the tower to be provided with cellular antenna mounting structure completewith working platform as specified in Clause 12.1 at the sites requested by the “**********”.

- For the locations requested by the “****”, the tower shall be provided withcomplete Six (06) pieces of cellular antenna mounting steelwork to which the antenna maybe rigidly attached by means of the mounting hardware supplied as a part of the antenna

- The adjustable microwave antenna mounting brackets should be provided at heights, whichwill specify once the location of the tower is decided. There shall be capability to installabove adjustable microwave antenna mounts in any height (on the slant or straight portion of the tower).

- Tower Suppliershall provide microwave antenna mounts for tower.

- Antenna boom shall be provided by GI pipes with 2.0m length, 115mm (4.5”) outer diameterand 4mm thickness

- Climbing Ladder

- The tower shall be provided complete with a climbing ladder vertically from ground level tothe top of tower. It shall be galvanized as the same quality for the tower.

- The ladder shall be fitted with a ladder guard with sufficient caging space ensuring safety.The ladder guard shall commence at a point 2.25m above ground level and above eachplatform, and shall be run continuously to underside of the platform above. A ladder guardshall be constructed of three vertical stringers with horizontal hoops at approximately One(01) meter spacing.

- Ladder shall continue for a distance of at least 1.5m above the upper surface of each

- No structural members of the tower shall protrude into or pass through the space within theladder guard.

- Ladder, ladder guards, and ladder supports shall not infringe on the space reserved for thefeeder cables.

- Ladder shall be adequately supported to resist lateral movement.

- Ladder steps shall be rough-surfaced preventing any slipping and hoops shall be paintedwith the same quality and color scheme of the tower.

- A horizontal ladder shall be provided from one leg to opposite leg at 30m and 50m heights.Walkways are needed and position could be adjusted with the bracing position.

Related posts

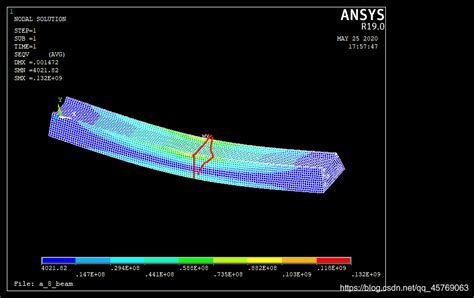

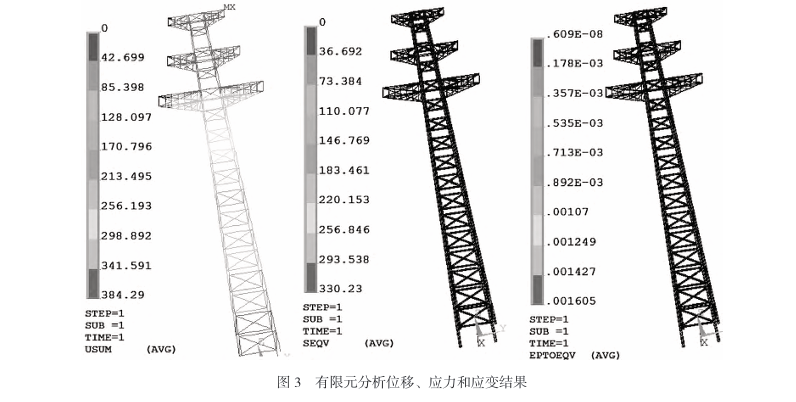

The analysis of the bearing capacity of a power transmission line steel tower highlights the complexity and importance of structural and foundation design. By understanding the interplay of loads, material properties, and environmental factors, engineers can optimize tower performance and ensure reliability in power networks. Tables and case studies further illustrate best practices and design considerations.