3 Legged Self Support Steel Tower , 4 Legged Tubular Tower

August 5, 2024

Guyed Towers in Electrical Transmission Lines Life-Cycle Assessment of Foundations

August 10, 2024Power Transmission Line Lattice Tower Comprehensive Technical Analysis

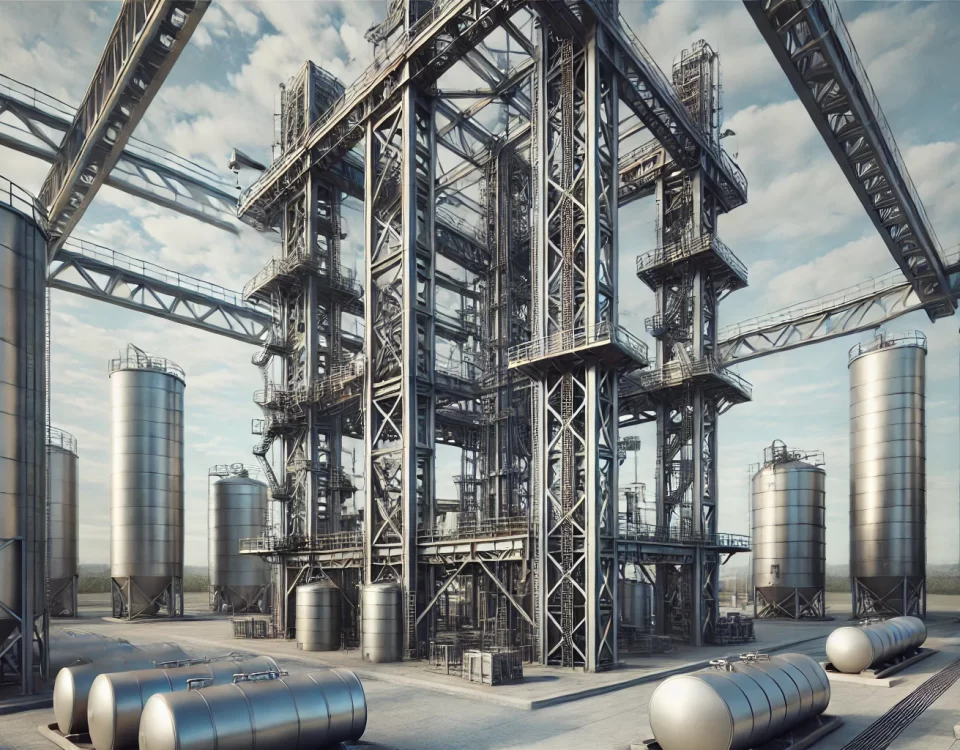

Introduction

Power transmission line lattice towers are critical infrastructure components that facilitate the efficient and reliable delivery of electrical energy over long distances. These towers support high-voltage power lines and ensure the stable transmission of electricity from power generation plants to substations and, eventually, to end users. This article aims to provide an in-depth technical analysis of power transmission line lattice towers, focusing on various aspects such as voltage ranges, tower types, material specifications, corrosion protection methods, and packing standards.

Summary Table

| Aspect | Details |

|---|---|

| Voltage Range | 10 kV, 66 kV, 110 kV, 220 kV, 230 kV, 500 kV |

| Tower Types | Suspension Tower, Tension Tower, Terminal Tower |

| Material Types | Q345B/ASTM A572 Gr50/S355JR, Q235B/ASTM A36/S235JO/SS400, Q420B/ASTM A572 Gr60/S420NL |

| Corrosion Protection | Galvanized, Galvanized + Painted |

| Packing Methods | By Bundles, Fasten Parts or Small Components Packed in Wooden Boxes or Steel Frames |

Electric Voltage Range

Voltage Specifications

Power transmission lines must operate at different voltage levels to accommodate varying distances and power capacities. The voltage range for these lines can include:

- 10KV: Typically used for smaller, localized distribution networks.

- 66KV: Commonly employed in medium-sized urban and rural power distribution.

- 110KV: Often used in regional transmission networks.

- 220KV: Suitable for long-distance high-capacity power transmission.

- 230KV and 500KV: Utilized in major national grids and international interconnections.

Voltage Impact on Tower Design

Each voltage level necessitates specific design considerations for the lattice towers:

- Insulation Requirements: Higher voltage levels require more robust insulation to prevent arcing.

- Physical Dimensions: Towers supporting higher voltages are generally taller and have wider bases to maintain safe clearance distances.

- Conductor Configuration: The number of conductors and their arrangement (e.g., bundled conductors for 500KV lines) vary with voltage levels to manage thermal and electrical stresses.

Tower Types

Suspension Towers

Suspension towers are designed to support the weight of the conductors and maintain their position under normal conditions. Key characteristics include:

- Lightweight Construction: These towers are relatively lightweight compared to tension towers.

- Flexibility: They allow for slight movements of the conductors due to wind or thermal expansion.

- Spacing: Placed at regular intervals along the transmission line to maintain conductor sag.

Tension Towers

Tension towers, also known as angle or dead-end towers, are used where the transmission line direction changes or at significant points such as river crossings. Key features include:

- Robust Structure: These towers are built to withstand the mechanical stresses of the conductor tension.

- Stability: They provide greater stability and support compared to suspension towers.

- Angle of Deviation: Designed to manage the angle of deviation in the transmission line, often up to 90 degrees.

Terminal Towers

Terminal towers are used at the endpoints of transmission lines, such as at substations or power plants. Their characteristics include:

- Heavy-Duty Construction: These towers are designed to handle the cumulative tension of the entire line.

- Anchoring: They provide anchoring points for the conductors, ensuring stability and security.

- Integration: Often integrated with substation infrastructure for seamless power delivery.

Material Types

Q345B/ASTM A572 Gr50/S355JR

Q345B, ASTM A572 Gr50, and S355JR are high-strength low-alloy structural steels commonly used in lattice towers due to their superior mechanical properties. Key attributes include:

- Yield Strength: Approximately 345 MPa, making them suitable for high-load applications.

- Weldability: Excellent weldability, facilitating construction and maintenance.

- Durability: High resistance to fatigue and impact, ensuring long-term performance.

Q235B/ASTM A36/S235JO/SS400

Q235B, ASTM A36, S235JO, and SS400 are carbon structural steels known for their versatility and cost-effectiveness. Characteristics include:

- Yield Strength: Approximately 235 MPa, suitable for moderate load applications.

- Formability: Good formability, allowing for easy fabrication into complex shapes.

- Availability: Widely available and economically priced.

Q420B/ASTM A572 Gr60/S420NL

Q420B, ASTM A572 Gr60, and S420NL are high-performance steels with enhanced strength and toughness. Features include:

- Yield Strength: Approximately 420 MPa, ideal for heavy-duty applications.

- Toughness: Superior toughness and resistance to brittle fracture, especially in low temperatures.

- Longevity: Extended lifespan, reducing maintenance needs and lifecycle costs.

Corrosion Protection

Galvanized

Galvanization involves coating the steel with a layer of zinc to protect against corrosion. Benefits include:

- Corrosion Resistance: Zinc acts as a sacrificial layer, preventing rust formation on the steel.

- Durability: Enhances the longevity of the tower by providing a robust protective barrier.

- Maintenance: Reduces the need for frequent maintenance and repairs.

Galvanized + Painted

Combining galvanization with painting offers enhanced protection. Advantages include:

- Double Layer Protection: The paint layer adds an extra barrier against environmental factors like UV radiation and chemical exposure.

- Aesthetic Appeal: Paint can improve the visual appearance of the towers, blending them with the surroundings.

- Extended Lifespan: Significantly increases the tower’s lifespan by providing comprehensive protection against corrosion.

Packing Standards

By Bundles

Packing by bundles is a common method for transporting tower components. Features include:

- Efficiency: Facilitates easy handling and transportation.

- Protection: Bundles are secured to prevent damage during transit.

- Organization: Ensures components are organized and readily accessible upon delivery.

Fasten Parts

Fastening parts together involves securing smaller components to prevent loss or damage. Key points include:

-

- Security: Ensures all parts are securely fastened and protected.

- Convenience: Simplifies assembly by keeping related components together.

- Integrity: Maintains the integrity of parts during transportation.

Small Components Packed in Wooden Boxes or Steel Frames

Packing small components in wooden boxes or steel frames provides added protection. Benefits include:

- Protection: Prevents damage to delicate or critical components.

- Organization: Keeps small parts organized and easy to locate.

- Durability: Wooden boxes and steel frames offer robust protection against environmental factors and handling stresses.

Conclusion

Power transmission line lattice towers are essential for the reliable and efficient delivery of electrical energy across vast distances. Understanding the technical aspects, including voltage ranges, tower types, material specifications, corrosion protection methods, and packing standards, is crucial for designing and maintaining these critical infrastructure components. By adhering to these detailed specifications and standards, we can ensure the long-term performance and stability of power transmission networks, ultimately contributing to the consistent and reliable supply of electricity to end users.

FAQ

1. What are the main types of power transmission line lattice towers?

The main types of power transmission line lattice towers are suspension towers, tension towers, and terminal towers, each designed for specific applications and mechanical requirements.

2. What materials are commonly used for constructing lattice towers?

Common materials for constructing lattice towers include Q345B/ASTM A572 Gr50/S355JR, Q235B/ASTM A36/S235JO/SS400, and Q420B/ASTM A572 Gr60/S420NL, each offering different levels of strength and weldability.

3. How is corrosion protection achieved for lattice towers?

Corrosion protection for lattice towers is typically achieved through hot-dip galvanizing or a combination of galvanizing and painting, providing excellent resistance to environmental factors.

4. What voltage levels do lattice towers support?

Lattice towers support various voltage levels, including 10KV, 66KV, 110KV, 220KV, 230KV, and 500KV, each requiring specific design considerations.

5. How are lattice tower components packed for transportation?

Lattice tower components are packed using methods such as bundling for large components and wooden boxes or steel frames for smaller parts and fasteners, ensuring safe and efficient transportation.