400KV Transmission Line Lattice Steel Tower Design drawings Requirements

April 15, 2018

The application and the history of steel

April 16, 2018Power transmission line steel tower Inspection and Tests, Packing,Transportation

Inspection and Tests

a) General

The Contractor shall make adequate tests and inspections to determine whether the material furnished is strictly in accordance with this Specification. In addition, the Employer may inspect and accept or reject the material made under this Specification either at the Contractor’s plant or at the point of delivery.

The Employer’s representatives shall have access to all parts of the Contractor’s plant concerning the work while this is in progress. The Contractor, without requesting any fee, shall provide all reasonable facilities to the Employer’s representatives so as to satisfy them that the towers are manufactured strictly in compliance with this Specification and the highest industry standards.

Where required by the Employer, the Contractor shall successfully test prototypes of towers in the presence of the Engineer in accordance with rigging drawings and loading programme, prepared by the Contractor and approved by the Engineer.

| Product Name | Angle Tower |

| Type |

Angle steel, Angular tower, Communication tower, Lighting rod tower, Radio and television tower, Electrified railway structure, Substation architecture Telecommunication tower |

| Material |

Q235 or Q345 |

|

Welding |

CO2 welding or Submerged arc auto methods |

|

Voltage Grade |

10kv~1000kv |

|

Surface Coating |

Galvanization |

|

Certificate |

ISO9001 |

|

Lifetime |

More than 30 years |

The Contractor shall furnish certified test reports giving the loads applied, tower deflections and other test results as specified in the tower testing programs approved by the Engineer.

- b) Material Tests

Regardless of whether the material is inspected by the Employer, the Contractor shall furnish certified test reports as follows:

- Steel mill test reports showing chemical and physical properties of the material to be furnished under the Contract.

- A manufacturer’s certificate of Inspection for hot-dip galvanized coatings on structural steel with the following information:

- Purchase order number.

- Date of inspection.

- Number of pieces tested for weight of zinc coating with maximum, minimum and average weights for each.

- Number of pieces tested for adherence of coating.

- Number of rejections because of defective coating and other reasons.

- c) Tower Tests

Full scale tower load tests of assembled galvanized towers shall be carried out in accordance with the latest edition of Standards BSEN Publication No. 60652 (2004). The towers to be tested shall correspond to the maximum total height, including the body and/or leg extension.

The following requirements shall be fulfilled in the load tests of the tower:

|

a) |

The members in a test tower shall be of the same grade and quality of fabrication as those to be supplied for the towers under these Bid Documents. The Contractor shall furnish certified test reports of the heats from which the material was rolled and a record showing the heat from which each member was obtained.

|

|

b) |

Test towers shall not be specially fitted other than with such fittings as are required on similar towers to be erected in the field.

|

|

c) |

Test towers shall be erected on a foundation structure, which shall be of adequate strength and stiffness to safely withstand the tower reactions under test loading, without noticeable distortion or displacement. The tower legs shall be connected to the anchorage in the same manner as to the normal stub angle at site.

|

|

d) |

The proposed test program shall be submitted to the Engineer for approval and shall include all load cases that cause critical loads in any member, together with diagrams indicating the proposed methods of applying the various loads and measuring of deflections. The Contractor shall calibrate dynamometers and gauges before testing the tower.

|

|

e) |

The test loads shall be those obtained from the design loads multiplied by the specified safety factor. Any combination of the test loads shall be applied to prove the capability of the structure to withstand all required loading.

|

|

f) |

Each tower shall withstand the test loads for at least five minutes without failure or permanent distortion of any member, fitting, bolt or part and without elongation of bolt holes. There shall be no adjustment of loads during the five minute period. Should it become necessary to adjust the loading, the five minute period shall restart after the adjustment is completed.

|

|

g) |

All test loads shall be removed completely before the loads for the next test are applied. Test loads corresponding to conductor and earth wire loading shall be applied to the attachments provided for these loads while test loads equivalent to wind load on the tower shall be applied in locations approved by the Engineer. Friction losses in rigging shall be taken into account in the application of the test loads.

|

|

h) |

Any conspicuous yielding or any failure under any of the test loading shall be considered as defect, in which case the Contractor shall modify the design and shall repeat at his own expense, the test case in which a defect developed.

|

|

i) |

After all defects, having developed during the regular tests, have been corrected and after the tower satisfactorily carries design loads multiplied by safety factors, the tower shall then be tested to destruction.

|

|

j) |

The Employer reserves the right to modify the requirements for performing any or all tests and the Contractor will not be entitled to any compensation by reason of such modification.

|

|

k) |

Test samples shall be cut from members which fail in destruction tests and standard tensile tests shall be performed at Contractor’s expense. The results of the tests on these samples shall be used to correct the assembled tower test results for comparison with design.

|

|

l) |

The Contractor shall submit full reports of all tower physical load tests including clear photograph of the test set-ups and nature of all failures, certified calibration reports, detailed diagrams showing the manner in which test loads were applied and deflection records.

|

|

m) |

The prices bided for tower tests shall include the cost of supplying, erecting, testing and dismantling of towers, together with all rigging, accessories, dynamometers, gauges, and personnel necessary for the conduct of the tests.

|

|

n) |

One tower structure of each type (with maximum height extension) shall be tested. No member of such tower shall be used further in the execution of the Contract.

|

|

o) |

Each tower structure shall be assembled with all step bolts/ladders in place. Engineer’s representative will test all climbing provisions for strict adherence to the specification and suitability, by climbing every tower completely. Any modifications found advisable during this test shall be incorporated into the tower design, without any extra cost. Notwithstanding prior approval given for tower drawings, design and location of all climbing provisions will be considered accepted only after Engineer’s confirmation, in writing, of their suitability, after successfully climbing the test towers.

|

- d) Shop Assembly

One tower of each type and height ordered, including every combination of leg extensions, shall be assembled in the shop to the extent necessary to assure correct fit of parts, adequate bolt lengths and proper field erection. Reaming of mismatched holes will not be permitted. A reasonable amount of drifting will be allowed in assembling. Shop-assembled parts shall be dismantled for shipment. Shop assembly shall be subject to approval by the Employer.

Packing and Transportation

All parts designed for bolting together shall be shipped unassembled.

Tower members shall be bundled together in the largest practical bundles for shipping and each bundle shall be clearly marked.

Bundles shall be securely fastened with tension tied steel bonds of sufficient tensile strength to support steel members during transit and yard handling. Each bundle shall be bonded 500 mm from each end with additional bonds equally spaced Small parts such as bolts, U-bolts and small clip angles shall be boxed and each box clearly marked for identification.

Railway wagons, ships or road trucks, in which steel is shipped, shall be reasonably clean and free from foreign materials, which could in any way injure the tower material. The boxes shall be lined with waterproof papers. An 8.0 cm clearance shall be maintained between bundles and floors.

Related posts

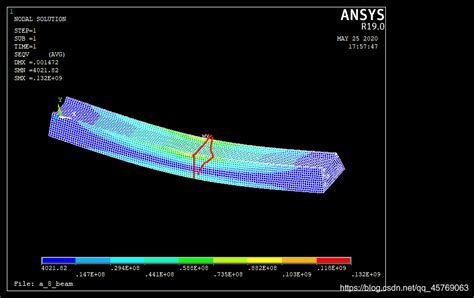

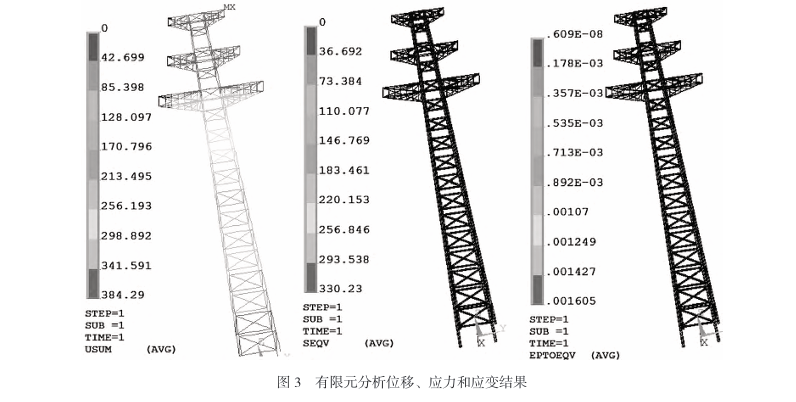

The analysis of the bearing capacity of a power transmission line steel tower highlights the complexity and importance of structural and foundation design. By understanding the interplay of loads, material properties, and environmental factors, engineers can optimize tower performance and ensure reliability in power networks. Tables and case studies further illustrate best practices and design considerations.