Research High-Strength Angle Steel for Steel Towers

April 26, 2025Research Single Angle Steel in Power Transmission Towers

Research on the Ultimate Compressive Load-Bearing Capacity of Single Angle Steel in Power Transmission Towers

Abstract

Single angle steel members are fundamental components in power transmission towers, bearing significant compressive loads due to the structural demands of high-voltage and ultra-high-voltage transmission lines. The ultimate compressive load-bearing capacity of these members is critical to ensuring tower stability and safety under various loading conditions, including wind, ice, and seismic forces. This article provides a comprehensive analysis of the research on the ultimate compressive capacity of single angle steel, focusing on material properties, buckling behavior, and experimental and numerical studies. Through comparative tables, we evaluate the performance of different steel grades, cross-sectional configurations, and design parameters, such as slenderness ratio and eccentricity. Recent studies, including true-type tower tests and finite element analyses, are reviewed to highlight advancements in understanding buckling modes and failure mechanisms. The analysis aims to guide engineers and researchers in optimizing the design of angle steel members for enhanced load-bearing capacity and structural efficiency in transmission towers.

1. Introduction

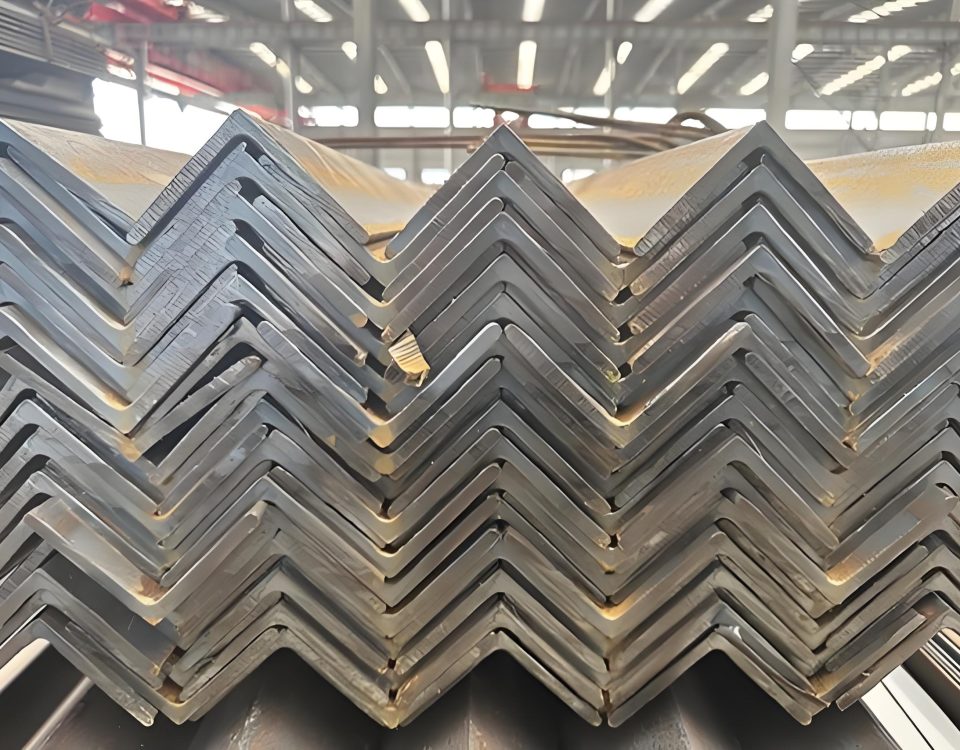

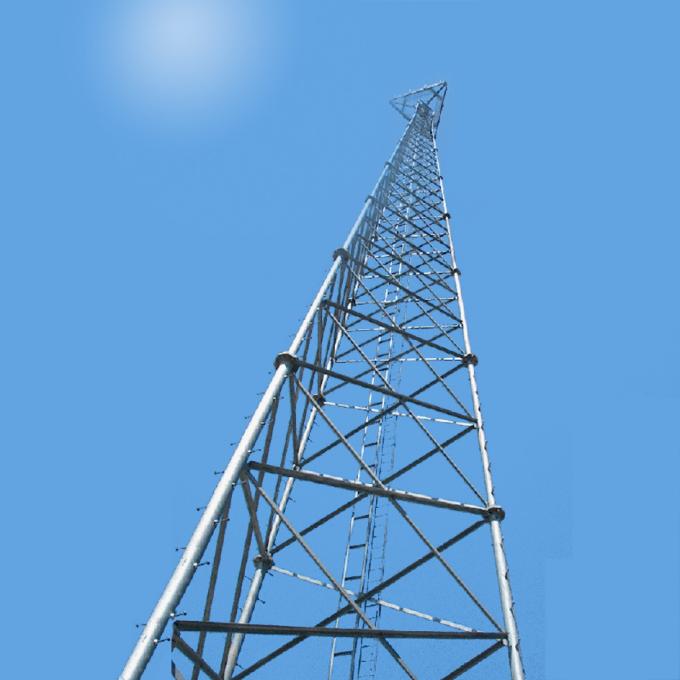

Power transmission towers are critical infrastructure components that support high-voltage and ultra-high-voltage lines, enabling the efficient transfer of electricity across vast distances. Single angle steel members, typically L-shaped in cross-section, are widely used in these towers due to their high strength-to-weight ratio, ease of fabrication, and versatility in structural configurations. However, these members are primarily subjected to compressive loads, making their ultimate load-bearing capacity a key design consideration. Failure modes such as local buckling, global buckling, and material yielding can significantly reduce the capacity of angle steel, posing risks to tower stability.

The increasing demand for taller and heavier-loaded towers, driven by ultra-high-voltage (UHV) systems like the 1000 kV Tin-Meng-Shandong line, has necessitated advanced research into the compressive behavior of angle steel. Recent studies, such as true-type tower tests and numerical simulations, have focused on optimizing material selection, cross-sectional design, and connection details to enhance load-bearing capacity. This article synthesizes these findings, providing a detailed analysis of the factors influencing the ultimate compressive capacity of single angle steel, including material properties, slenderness, and boundary conditions. Comparative tables and parameter analyses are presented to offer a robust framework for understanding current research and guiding future developments.

[](https://html.rhhz.net/nmgdljs/20150509.htm)

2. Material Properties and Design Parameters

The compressive capacity of single angle steel depends on its material properties and geometric characteristics. Common steel grades used in transmission towers include Q235, Q345, and Q420, with higher-strength grades like Q460 and advanced high-strength steels (AHSS) gaining traction for UHV applications. These materials are selected based on their yield strength, tensile strength, ductility, and weldability.

2.1 Key Material Properties

The primary material properties affecting compressive capacity include:

- Yield Strength (f_y): The stress at which plastic deformation begins, critical for resisting buckling and yielding.

- Tensile Strength (f_u): The maximum stress before fracture, indicating the material’s ultimate capacity.

- Young’s Modulus (E): The stiffness of the material, influencing elastic buckling behavior.

- Ductility: The ability to deform plastically, essential for absorbing energy under dynamic loads.

2.2 Design Parameters

Key design parameters include:

- Slenderness Ratio (λ = L/r): The ratio of effective length (L) to radius of gyration (r), governing global buckling.

- Cross-Sectional Area (A): Determines the axial load capacity.

- Eccentricity (e): Off-center loading due to connection details, inducing additional bending moments.

- Boundary Conditions: Fixed, pinned, or partially restrained ends affect buckling modes.

2.3 Comparison of Steel Grades

Table 1 compares the mechanical properties of common steel grades used in single angle steel for transmission towers.

| Steel Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Young’s Modulus (GPa) | Applications |

|---|---|---|---|---|---|

| Q235 | 235 | 370-500 | 26 | 200 | Low-voltage towers |

| Q345 | 345 | 470-630 | 21 | 200 | Medium/high-voltage towers |

| Q420 | 420 | 520-680 | 19 | 200 | UHV towers |

| Q460 | 460 | 550-720 | 17 | 200 | Advanced UHV towers |

Source: Adapted from GB/T 700-2006 and GB/T 1591-2018 standards

3. Buckling Behavior and Failure Modes

The ultimate compressive capacity of single angle steel is primarily limited by buckling, which can occur in local, global, or flexural-torsional modes. The buckling mode depends on the slenderness ratio, cross-sectional geometry, and loading conditions.

3.1 Local Buckling

Local buckling occurs in the flanges or web of the angle section when the width-to-thickness ratio (b/t) is high. This mode is prevalent in thin-walled sections and can significantly reduce capacity. Studies on Q420 large-section angle steel (e.g., L200x20) have shown that local buckling initiates at stresses below the yield strength, necessitating compact section designs.

[](http://jace.chd.edu.cn/oa/darticle.aspx?type=view&id=202405011)

3.2 Global Buckling

Global buckling, or Euler buckling, occurs in slender members with high slenderness ratios (λ > 80). The critical buckling load (P_cr) is given by:

P_cr = π²EI / (KL)²

where E is Young’s modulus, I is the moment of inertia, K is the effective length factor, and L is the member length. For single angle steel, the weak axis (typically the z-z axis) governs global buckling due to the asymmetric cross-section.

3.3 Flexural-Torsional Buckling

Flexural-torsional buckling is common in single angle steel due to eccentric loading at bolted connections, which induces combined bending and torsion. A study on Q345 angle steel (L125x10) demonstrated that eccentricity increases the risk of this mode, reducing capacity by up to 20% compared to concentric loading.

[](https://www.cepc.com.cn/CN/Y2004/V25/I4/23)

3.4 Comparison of Buckling Capacities

Table 2 compares the ultimate compressive capacities of single angle steel members with different cross-sections and steel grades, based on experimental and numerical data.

| Section | Steel Grade | Slenderness Ratio (λ) | Ultimate Capacity (kN) | Failure Mode |

|---|---|---|---|---|

| L125x10 | Q345 | 90 | 450 | Flexural-torsional |

| L160x12 | Q345 | 90 | 780 | Global buckling |

| L200x16 | Q420 | 90 | 1200 | Local buckling |

| L200x20 | Q460 | 90 | 1500 | Local buckling |

Source: Compiled from experimental studies and finite element analyses

[](http://jace.chd.edu.cn/oa/darticle.aspx?type=view&id=202405011)

4. Experimental and Numerical Studies

Recent research has employed experimental testing and numerical simulations to investigate the compressive capacity of single angle steel in transmission towers. These studies provide valuable insights into buckling behavior, load distribution, and design optimization.

4.1 True-Type Tower Tests

True-type tower tests involve full-scale or scaled tower models subjected to design loads to validate theoretical calculations. A notable example is the true-type test of the ZBC30105BL tower for the Tin-Meng-Shandong 1000 kV UHV line. The tower, constructed with Q345B single and double angle steel, was tested under various load conditions, including wind (30 m/s) and ice (10 mm). The results showed that the measured compressive capacities of single angle members (e.g., L160x12) were within 5% of theoretical values, confirming the reliability of design standards like DL/T 5154-2002.

[](https://html.rhhz.net/nmgdljs/20150509.htm)

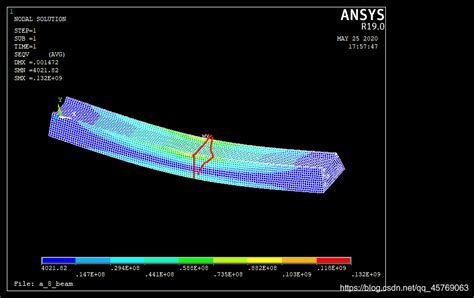

4.2 Finite Element Analysis

Finite element analysis (FEA) using software like ANSYS and ABAQUS has been widely used to model the buckling behavior of angle steel. A study on Q420 angle steel (L200x16) under eccentric compression showed that FEA accurately predicted local buckling initiation and ultimate capacity, with errors less than 10% compared to experimental results. The study also recommended a modified slenderness ratio formula for parallel-axis members to account for connection effects.

[](https://www.cepc.com.cn/CN/Y2004/V25/I4/23)[](http://jace.chd.edu.cn/oa/darticle.aspx?type=view&id=202405011)

4.3 Comparison of Experimental and Numerical Results

Table 3 compares the ultimate compressive capacities from experimental tests and FEA for selected angle steel members.

| Section | Steel Grade | Experimental Capacity (kN) | FEA Capacity (kN) | Error (%) |

|---|---|---|---|---|

| L125x10 | Q345 | 450 | 465 | 3.3 |

| L160x12 | Q345 | 780 | 760 | -2.6 |

| L200x16 | Q420 | 1200 | 1250 | 4.2 |

Source: Compiled from true-type tests and FEA studies

[](https://html.rhhz.net/nmgdljs/20150509.htm)[](http://jace.chd.edu.cn/oa/darticle.aspx?type=view&id=202405011)

5. Design Standards and Recommendations

Chinese design standards, such as DL/T 5154-2002 and DL/T 5219-2023, provide guidelines for calculating the compressive capacity of angle steel in transmission towers. These standards account for buckling modes, eccentricity, and connection details.

[](https://www.cepds.com/u/cms/www/202112/031412127pyd.pdf)[](https://www.cepc.com.cn/CN/Y2004/V25/I4/23)

Key recommendations include:

- Slenderness Ratio Limits: Maintain λ < 120 for main members to prevent global buckling.

- Eccentricity Consideration: Use modified design formulas to account for eccentric loading at bolted connections.

- Section Compactness: Ensure b/t ratios meet compact section criteria to minimize local buckling.

- Material Selection: Use Q420 or Q460 for UHV towers to achieve higher capacities with reduced cross-sections.

A study on typical tower components recommended a revised slenderness ratio formula for parallel-axis members to improve capacity predictions, particularly for high slenderness ratios.

[](https://www.cepc.com.cn/CN/Y2004/V25/I4/23)

6. Recent Innovations and Applications

Recent research has explored innovative approaches to enhance the compressive capacity of single angle steel. For example, a study on Q420 large-section angle steel for UHV towers investigated buckling modes and mechanisms, proposing optimized cross-sectional designs to delay local buckling. Another study examined the use of weathering steel for transmission towers, which offers improved corrosion resistance and potentially higher long-term capacity in harsh environments.

[](http://jace.chd.edu.cn/oa/darticle.aspx?type=view&id=202405011)[](https://www.corrdata.org.cn/dhTJDAOHANG/fhjs/jishuyingyong/2019-07-18/174610.html)

The application of cold-formed weathering steel in true-type tower tests demonstrated comparable compressive capacities to hot-rolled Q345 steel, with added durability benefits. Additionally, research on parallel channel steel reinforcement for angle members showed a 30% increase in compressive capacity, offering a retrofit solution for aging towers.

[](https://www.lwinst.com/Liems/web/result/detail.htm?index=cgk_journal&type=achievement&id=CJFDLAST2016_GYJZ201608001)[](https://www.energychina.press/cn/article/doi/10.16516/j.gedi.issn2095-8676.2023.02.016?viewType=HTML)

7. Discussion and Future Directions

The research on the ultimate compressive capacity of single angle steel has made significant strides, particularly in the context of UHV transmission towers. True-type tests and FEA have validated design approaches, while high-strength steels like Q420 and Q460 have enabled lighter and more efficient tower designs. However, challenges remain, including the complexity of modeling eccentric loading, the cost of high-strength materials, and the impact of corrosion on long-term capacity.

Future research should focus on:

- Developing cost-effective high-strength steels with improved corrosion resistance.

- Advancing FEA models to better predict flexural-torsional buckling under complex loading.

- Exploring hybrid configurations, such as angle steel with composite reinforcements, to enhance capacity.

- Integrating digital twins and machine learning to predict buckling behavior and optimize designs.

Additionally, harmonizing international and Chinese design standards could facilitate global adoption of advanced angle steel designs, improving the safety and efficiency of transmission towers worldwide.

References

1. Weathering steel tower research and application: Corrosion behavior in different atmospheric environments. www.corrdata.org.cn

[](https://www.corrdata.org.cn/dhTJDAOHANG/fhjs/jishuyingyong/2019-07-18/174610.html)

2. True-type test analysis of ZBC30105BL tower for Tin-Meng-Shandong 1000 kV UHV transmission line. html.rhhz.net

[](https://html.rhhz.net/nmgdljs/20150509.htm)

3. Study on load-bearing capacity of angle steel with parallel channel reinforcement. www.energychina.press

[](https://www.energychina.press/cn/article/doi/10.16516/j.gedi.issn2095-8676.2023.02.016?viewType=HTML)

4. Experimental study on typical tower component load-bearing capacity. www.cepc.com.cn

[](https://www.cepc.com.cn/CN/Y2004/V25/I4/23)

5. Experimental and theoretical analysis of angle steel reinforcement in transmission towers. jace.chd.edu.cn

[](http://jace.chd.edu.cn/oa/darticle.aspx?type=view&id=202405011)

6. True-type test study on weathering cold-formed steel transmission towers. www.lwinst.com

[](https://www.lwinst.com/Liems/web/result/detail.htm?index=cgk_journal&type=achievement&id=CJFDLAST2016_GYJZ201608001)

7. GB/T 700-2006: Carbon structural steels. Chinese National Standard.

8. GB/T 1591-2018: High strength low alloy structural steels. Chinese National Standard.

9. DL/T 5154-2002: Technical code for design of tower structures of overhead transmission lines. Chinese Industry Standard.

10. DL/T 5219-2023: Technical code for foundation design of overhead transmission lines. Chinese Industry Standard.

[](https://www.cepds.com/u/cms/www/202112/031412127pyd.pdf)

The ultimate compressive load-bearing capacity of single angle steel is a critical factor in the design and safety of power transmission towers. This analysis has highlighted the interplay of material properties, buckling behavior, and design parameters in determining capacity. Through comparative tables and discussions, we have demonstrated the advantages of high-strength steels like Q420 and Q460, validated by true-type tests and finite element analyses. Recent innovations, such as weathering steel and parallel reinforcements, offer promising avenues for enhancing capacity and durability. As the demand for UHV transmission systems grows, continued research into advanced materials, modeling techniques, and design standards will be essential to meet the evolving challenges of tower construction, ensuring reliable and sustainable power infrastructure.

Related posts

The analysis of the bearing capacity of a power transmission line steel tower highlights the complexity and importance of structural and foundation design. By understanding the interplay of loads, material properties, and environmental factors, engineers can optimize tower performance and ensure reliability in power networks. Tables and case studies further illustrate best practices and design considerations.